Increasing process and user safety with a medical UV curing system developed according to GAMP 5

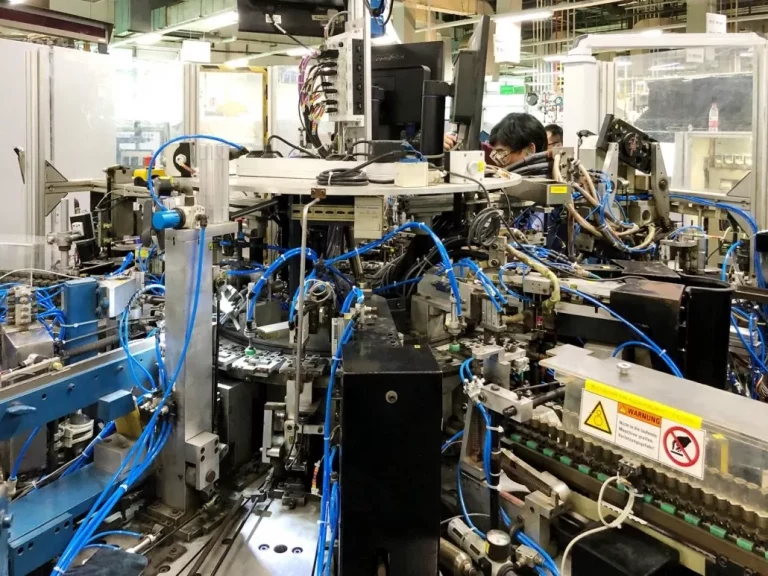

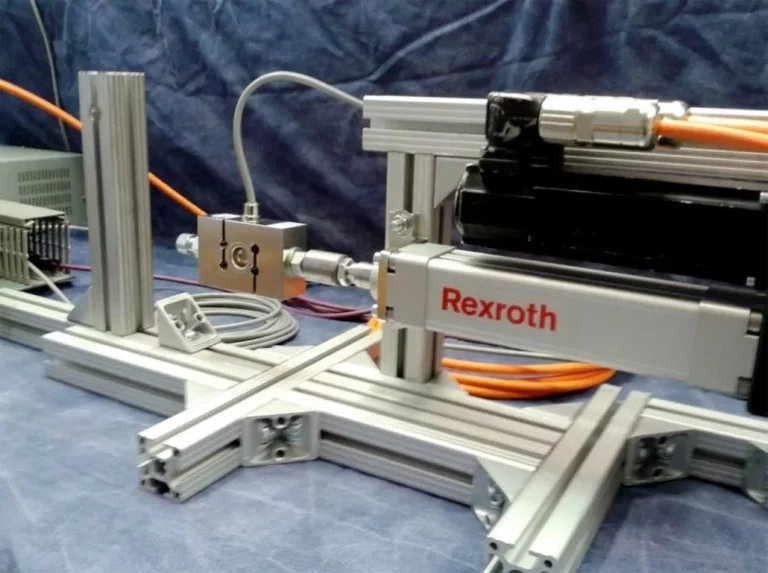

A new design and safety features have increased the efficiency and safety of a curing process using UV light. The validation of the system was carried out according to GAMP 5.