Optical inspection

As an authorised system partner and main integrator of Keyence Deutschland GmbH for several years, the solution of complex tasks is one of our core competences.

Services Image processing

Services Image processing

Our machine vision department has been successfully developing and implementing applications in industrial environments for more than 15 years. Our team consists of experts who specialise in specific application areas and hardware and software solutions.

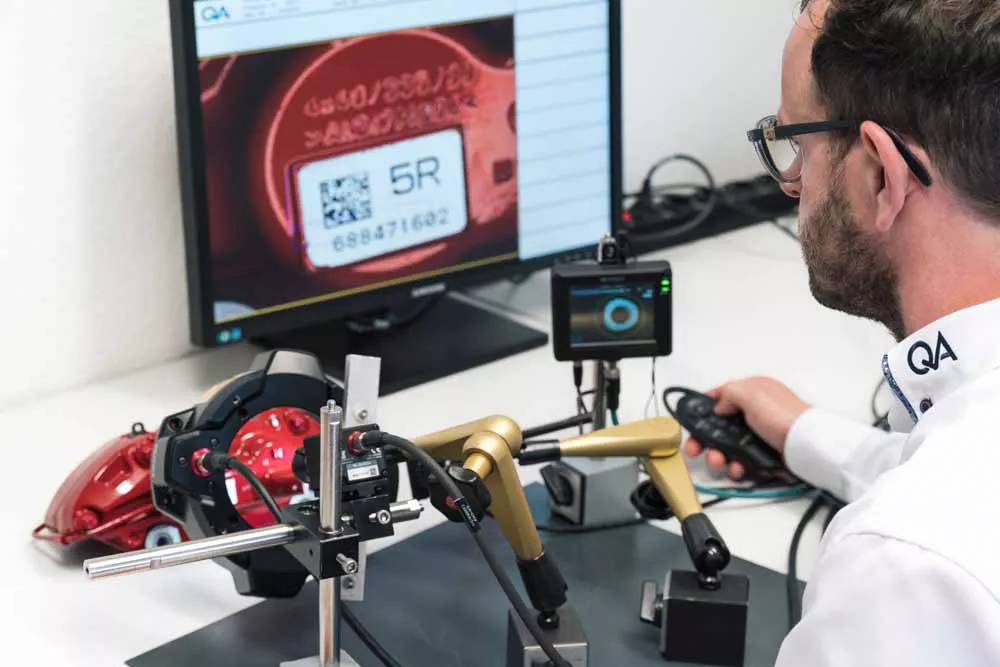

In the field of contactless measuring systems, the team of experts at Quality Automation GmbH provides you with its expertise and experience in the areas of surface analysis as well as geometry, rotary position and presence inspection worldwide. We also utilise the latest technologies such as deep learning and AI. Our dedicated team is in constant dialogue with you to overcome the challenges of your specific application at the highest level.

To ensure functional reliability during subsequent operation, there is always the option of carrying out a feasibility study prior to installation in process operation. This is realised through a test setup in one of our test laboratories and presents potential implementation alternatives.

Preliminary investigation of image processing solutions

Do you have a problem that you would like to solve with image processing? But you’re not sure whether it’s technically feasible or how much it would cost? Then you’ve come to the right place!

We invite you to a non-binding preliminary examination in which we carefully analyse and evaluate your problem. We carry out initial tests with your products in our laboratory and check which image processing solutions are suitable for your requirements. We document the results and show you what is possible and what is not.

Based on the preliminary examination, we can then offer you various options for further co-operation. Once the task has been clearly defined and a stable solution has been found, we can make you a customised offer for the realisation of your project. If the task requires further investigation, we can propose a feasibility study in which we develop the optimum image processing solution for you.

We are experts in industrial image processing and have many years of experience in various industries and applications. We work with state-of-the-art technology and software and guarantee you the highest quality and reliability.

Feasibility study for image processing

Do you have a complex or unusual image processing task for which there are no standard solutions? Would you like to know whether and how we can solve your problem? Then a feasibility study for image processing is just the thing for you!

A feasibility study for image processing is a comprehensive and customised examination of your problem. We test various lighting and camera systems to find the optimum solution for your requirements. We also take your own wishes and ideas into account when selecting and implementing the system. We document every step of the study and explain to you in detail how we arrived at the solution. You will receive complete documentation with all the dimensions and components used that you need for your image processing solution.

Realisation of image processing projects

Have you found an image processing solution that solves your problem? Would you like to integrate this solution into your existing system or build a new machine with image processing? Then we are your ideal partner!

Training in image processing and familiarisation with image processing projects

Have you received an image processing solution from us or would you like to learn more about image processing? We offer professional training and instruction tailored to your needs and requirements.

We will show you how to operate, adjust, optimise and maintain your image processing solution. We explain the basics and functions of image processing and answer your questions. We give you tips and tricks on how to use your image processing solution efficiently and effectively.

We carry out the training and instruction at your premises or at our premises. We provide you with all the necessary documents and materials. We cater to your individual wishes and problems and adapt the training and instruction to your level and pace.

Optimisation of image processing projects

Do you have a vision system that no longer meets your requirements or expectations? Would you like to improve the performance, quality or reliability of your image processing system? Then we are the people to contact!

We offer you a professional optimisation of your image processing system that is tailored to your needs and objectives. We analyse your existing image processing system and identify the existing problems and weak points. We show you the optimisation potential and the possible solutions. We implement the optimisation solutions and test the results. We check the improvements and ensure that you are satisfied with your optimised image processing system.

We have many years of experience in optimising image processing projects for various industries and applications. We work with state-of-the-art technology and software and utilise the latest findings and methods in image processing. We guarantee effective and cost-efficient optimisation of your machine vision system.

As an authorised system partner and main integrator of Keyence Deutschland GmbH for several years, the solution of complex tasks is one of our core competences.

Our experts offer holistic support in 3D image processing, from feasibility studies to project planning and integration.

We continuously research the topic of Deep Learning and pass on our knowledge to our customers.

Since its foundation in 2000, Quality Automation GmbH has been one of the leading providers in the fields of production and manufacturing automation.