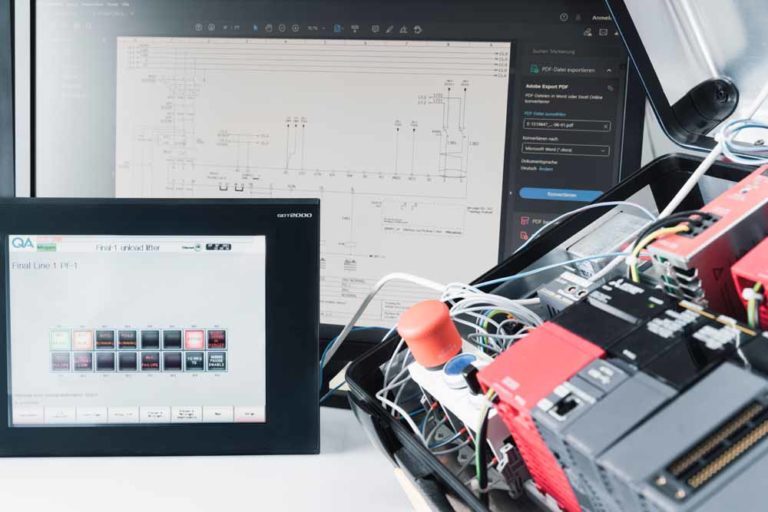

Real-time control of a Mitsubishi Electric robot

Through a special real-time mode, the movements of the robot can be changed at runtime.

The control data is provided by a synchronized multi CPU system.

Services Automation Robotics

Services Automation Robotics

We are your partner for robot-based automation. Together we plan, develop, design, programme and implement all the components required for successful automation – turnkey!

Our experts in the field of robotics are always there for you. From detailed planning and subsequent realisation to accompanying training. We specialise in industrial robots from the following manufacturers:

Controlling the robots via image processing solutions contributes significantly to optimising the production process. In this way, even components that were previously integrated manually can be assembled with the highest precision. In addition, products can be reliably passed on to the next production step without errors. In robotics, we work closely with our colleagues from our image processing department to achieve the best possible result for our customers. We successfully use 2D, 3D or AI-supported image processing.

Years of experience and many successfully implemented, complex projects with robots from Kuka make us experts. We not only realise standard applications, but also program in the customer’s own development environments – naturally in accordance with all valid group standards. With an additional certification, we are authorised to implement Kuka’s SafeOperation option package. We implement this regularly in order to monitor work areas safely.

Handling of glass substrates in glove boxes

Handling of engine blocks between several furnaces as well as water basin for quenching, stamping station and cooling tunnel

In cooperation with the company Hille Engineering, this winding application was implemented for the Institute for Plastics Processing (IKV) in Industry and Trade at the RWTH Aachen. The IKV is Europe’s leading research and training institute in the field of plastics technology.

Mitsubishi robots are successfully used by customers and in research projects. Mitsubishi has high-precision and intelligent technologies to increase productivity. In manufacturing cells or production lines, we often implement these in combination with a Mitsubishi PLC or other industrial automation devices.

Learn more about the real-time control of a Mitsubishi Electric robot in this reference project.

Through a special real-time mode, the movements of the robot can be changed at runtime.

The control data is provided by a synchronized multi CPU system.

We have unique know-how and competences with unique selling points in our main areas of expertise.

We are a licensed Certified Excellence Solution Partner of Bosch Rexroth and a certified Siemens Solution Partner.

From detailed planning and implementation to accompanying training – trust our experts in the field of robotics!

Since its foundation in 2000, Quality Automation GmbH has been one of the leading providers in the fields of production and manufacturing automation.