Electrical design

Whether retrofit or new installation, our team will provide you with a complete turnkey solution in close cooperation.

Services Construction & Manufacturing Assembly manufacturing

Services Construction & Manufacturing Assembly manufacturing

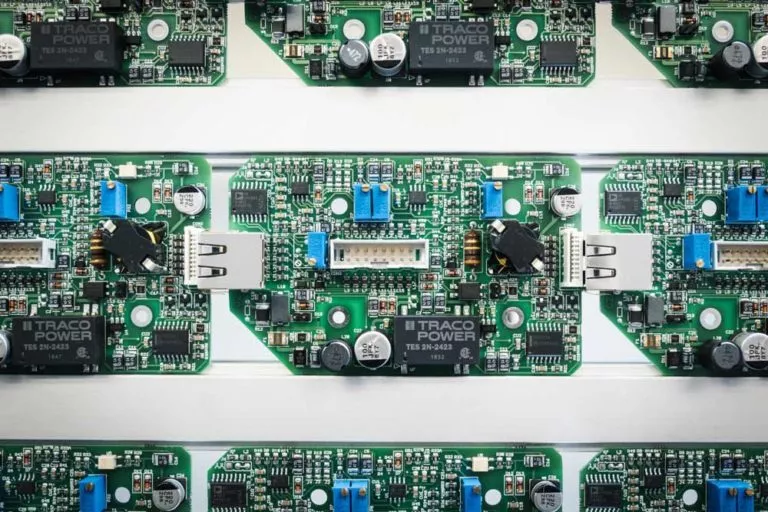

Special requirements cannot always be implemented with conventional automation systems. The Electronics department of Quality Automation GmbH from Stolberg near Aachen closes this gap and integrates customized electronic assemblies into the automation process, which can be prototypes as well as small series. Thus, it offers you the optimal solution to achieve jointly defined goals.

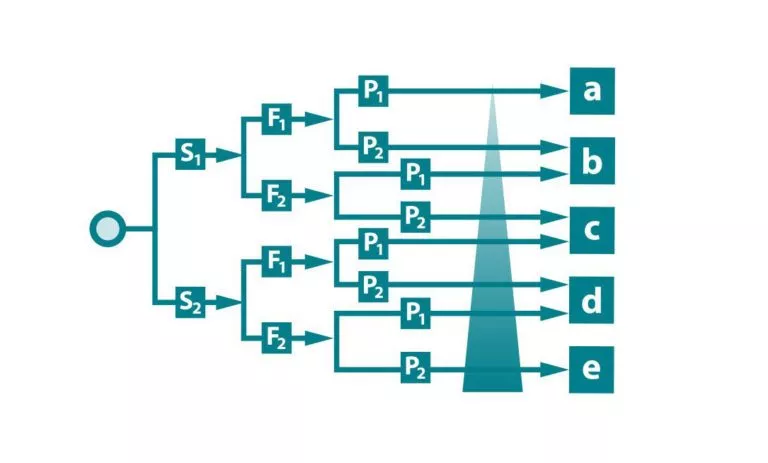

The circuit diagram is created with the CAD tool EAGLE. After analysing the problem, a pure hardware solution or the use of a microcontroller may be appropriate.

After optical inspection, all manufactured assemblies are subjected to an electrical function test. Depending on the complexity and quantity, automated test systems are used for this purpose. After production and function test in the laboratory, the system is integrated at the place of use, if required and depending on the application, and tested again under real conditions before delivery.

Quality Automation GmbH also provides a support service after delivery of the systems. Defective assemblies are repaired and returned to the customer fully tested. Long-term support can be guaranteed by keeping special components and test systems in stock.

Whether retrofit or new installation, our team will provide you with a complete turnkey solution in close cooperation.

Our experts in switch cabinet construction accompany you from the development to the construction to the finished switch cabinet.

We support you in the implementation of the Machinery Directive. From risk assessment to CE marking and logging.

We help you turn your visions into manufacturable products or optimise existing designs.

Our Electronics department integrates customised electronic assemblies into the automation process.

Since its foundation in 2000, Quality Automation GmbH has been one of the leading providers in the fields of production and manufacturing automation.