Innovative camera-supported robot control

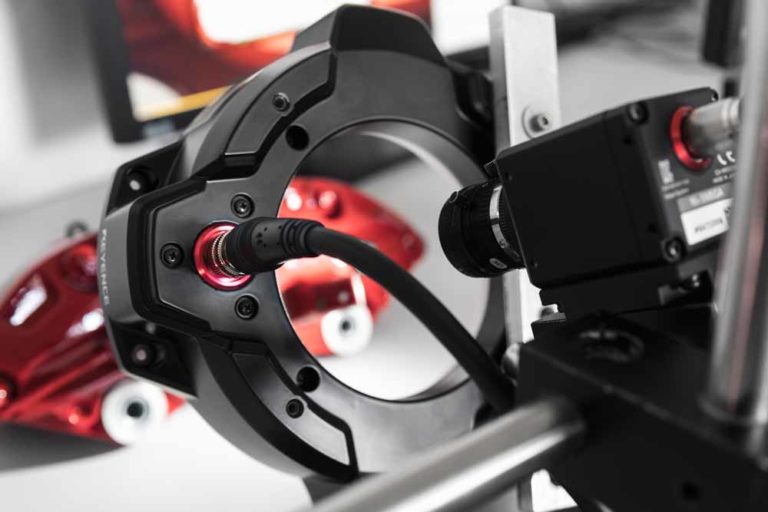

By using plug&play a fast connection of the camera to the robot control is possible. Gotten information from image data can be converted directly into position data.

Services Image processing Optical inspection

Services Image processing Optical inspection

Due to the constantly increasing demands on product quality and documentation, industrial image processing has become a key technology whose sales figures are rising rapidly, not least because of the compact system solutions that are now available. Machine vision is used wherever the task would be too dangerous for a human, would lead to fatigue and thus loss of concentration or where the requirements exceed the capabilities of a human.

Are you looking for a powerful and flexible solution for your image processing applications? Then our PC-based system is just right for you. It consists of several software components that are optimally harmonised and give you full control over your image processing.

We use LabView to realise the user interface, which is individually designed according to your wishes and requirements. You can concentrate fully on your image processing without being distracted by the operating system. LabView also enables you to communicate easily with other systems via versatile protocols such as OPC UA, EthernetIP and more. You can communicate at field level with PLCs or other systems, use database connections or connect other PC systems.

Our experts successfully use the Halcon image processing library from MVTec Software GmbH for optical inspection. With a total of more than 2,000 operators in the image processing library, Halcon is one of the leading software solutions on the market and offers a significantly expanded range of functions. In combination with our many years of expertise, this enables us to solve the most complex requirements where standard tools from other manufacturers reach their limits.

From image acquisition to image processing and image evaluation, Halcon also allows you to utilise the latest technologies, such as AI-based deep learning, to make your image processing even more powerful and precise.

Our PC-based image processing system is the ideal solution for anyone looking for high-quality, flexible and future-proof image processing. Contact us today and let us advise you!

You can find a current example of industrial image processing in our reference projects:

By using plug&play a fast connection of the camera to the robot control is possible. Gotten information from image data can be converted directly into position data.

Thanks to our long-standing partnerships with market-leading manufacturers, we are able to utilise the most optimal system for our customer’s application.

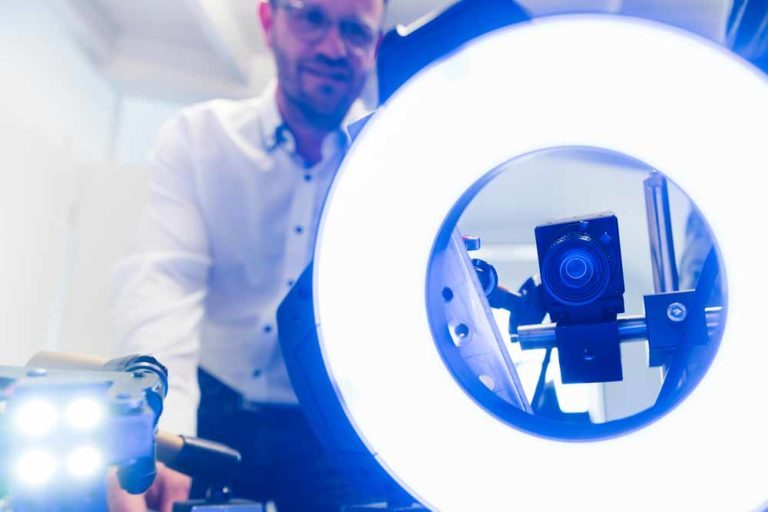

Many machine vision projects begin with a preliminary investigation or feasibility study if there is uncertainty regarding the choice of hardware or the general feasibility. The extensive studies are carried out in our own vision laboratory. We support you in the realisation of your machine vision project from start to finish and beyond. Not only do we take care of selecting the right hardware and software components, but our broad service portfolio also enables us to integrate the components mechanically and electrically into your system. We commission your new system and optimise the parameters for the best possible performance.

As an authorised system partner and main integrator of Keyence Deutschland GmbH for many years, the solution of complex tasks is one of our core competencies. We offer you comprehensive support from the feasibility study through project planning to the final integration.

We are a licensed solution partner of Balluff GmbH in the field of image processing. In joint projects, we use industrial cameras, high-performance AI systems, embedded components, our own software suites and industrial-grade accessories such as lenses and lighting. The broad product range of the medium-sized, family-run company is constantly being expanded and always offers innovative image processing components for the requirements of our customers.

As an authorised system partner and main integrator of Keyence Deutschland GmbH for several years, the solution of complex tasks is one of our core competences.

Our experts offer holistic support in 3D image processing, from feasibility studies to project planning and integration.

We continuously research the topic of Deep Learning and pass on our knowledge to our customers.

Since its foundation in 2000, Quality Automation GmbH has been one of the leading providers in the fields of production and manufacturing automation.