You are currently viewing a placeholder content from YouTube. To access the actual content, click the button below. Please note that doing so will share data with third-party providers.

More InformationKeyence Robot Vision

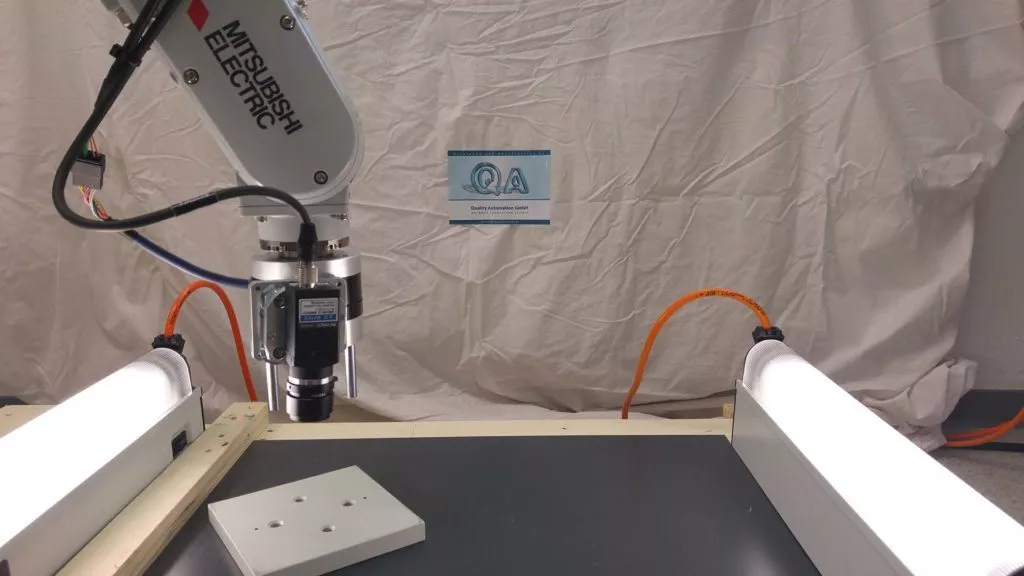

The new function Robot Vision, offered by Keyence for its types CV‑X und XG, enables a simple camera supported robot control. Interfaces for a plurality of robot producers are offered that make a supplementary integration of the product also in existing plants possible. The company Quality Automation GmbH has transferred and tested the function with a robot of Mitsubishi Electric in a test preparation.

Installation and calibration

According to the application it is possible to fix the camera directly on the robot or attach it securely in the surrounding area. The controller of the camera and the robot are connected via Ethernet and communicate immediately with each other after implementation of the installation program of Keyence. Thus, for a more simple installation the robot can directly be controlled by the Keyence controller. As soon as the camera is well-positioned and the connection between camera and robot is built the first images can be taken and the image processing can be started. In order to transfer image elements into position data a calibration has to be done. For that Keyence offers an automatic calibration showing advantages compared to manual methods like being more precise, repeatable and independent of user and installation location of the robot. The result of the calibration is a specification for a conversion of detected pixels on the camera image into Cartesian coordinates for the robot.

Possibilities of application

In case of the test preparation of the company Quality Automation GmbH the camera was fixed on the robot and a pick & place application was successfully put into operation. Besides the simple position detection of objects the function can also be used for more complex tasks like quality assurance. For that large surfaces can be inspected and tested by the robot. The position of damages is given or marked directly. Also the right assembly of a conductor board can be carried out or checked with that method. Moreover, the camera supported control is suitable for the assembly of component parts, e.g. for putting on adhesives or for fixing of screws. In case that the camera is attached securely in the surrounding area a correction of the grab can be done by that function. For that the robot drives over the camera with the picked object, the position of the grab is analyzed and corrected if necessary.