Mitsubishi Force Sense Function

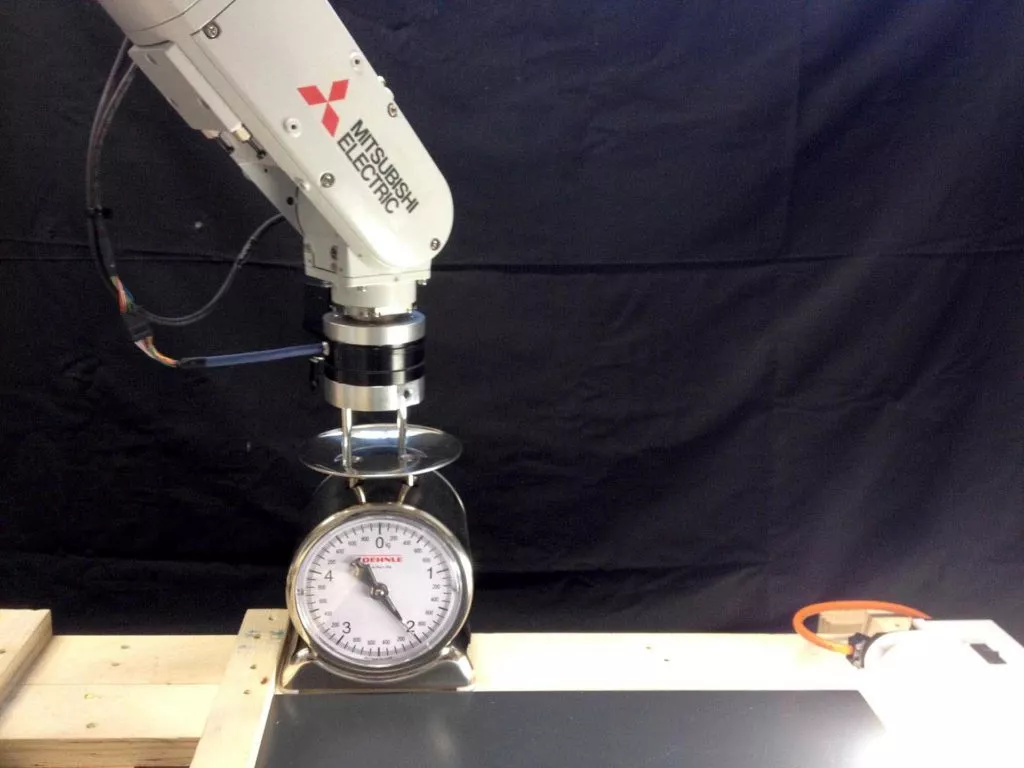

The Force Sense Function of Mitsubishi uses the measured data of the sensor being able to measure forces and torques in all 6 variances to communicate a “feeling” of its power to the robot. By different modes the function offers a wide palette of control and supervising possibilities. The company Quality Automation GmbH has started up and tested the function with a force sensor and Mitsubishi robot in its particular experimental set-up.

constant power raising –> connecting process in stiffness mode

Installation of components

The used sensor is a capacitive force torque sensor for 6 variances of Mitsubishi that is possible to measure forces and torques with a resolution of 0,03N respectively 0,0006Nm. It is mounted by an adapter plate between hand flange and robot hand (effector). A serial interface to the data exchange and a power supply are already obstructed in the robot and can be directly led through the arm and connected to the sensor. By a force sensor unit the power supply and the data cable are connected to the control unit of the robot.

Functional range and application possibilities

In that case that the force is used as input parameter of the control system the modes stiffness or force can be taken. When using the stiffness-mode the robot kinematics acts on the effector like a spring with certain stiffness and gives way to the force effect in case of collision or exterior force effect. In that mode the robot can react in a smooth way to process deviations like tolerances in case of positioning of assembling components and can correct its path and surrounding correspondingly. When using the force mode the robot moves on its path by keeping the provided forces respectively torques. This mode can be used for improvement of processes of machining like grinding and polishing of surfaces. Besides the modes detection and log can be taken in case of collision supervising or simple measurement data registration and storing. The measurement data can be used in the quality assurance and for test systems. Thus the feel or the attitude of a product can be analyzed by permanent stress in a long time test.