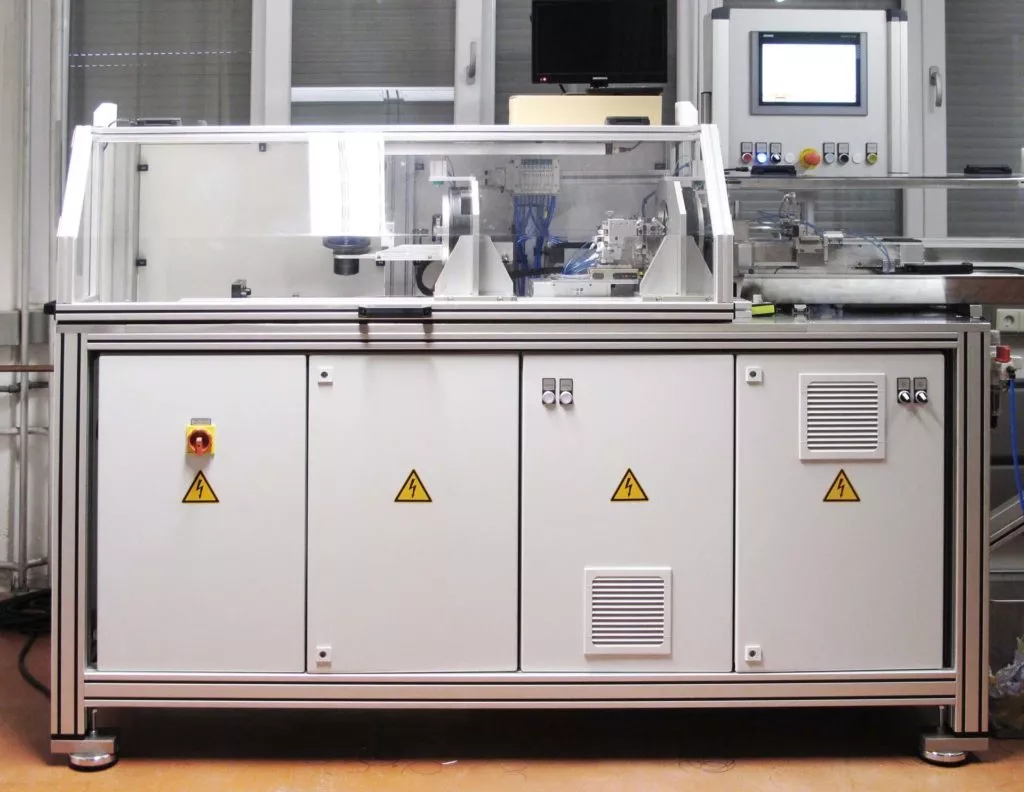

Thread cutting machine, heart of the machine: the yarn infeed and cutting

Long auxiliary process times and manual intervention with previous production lines

The processed products are monofilament threads with a diameter of 0.25 to 1.0 mm, which are provided with a specific profile in the form of indentations. These sutures are used, for example, for cosmetic corrections such as facelifts, but also for wound closure. The profiles differ in the number, depth, shape and orientation of the indentations. The machines previously used for production could only be used for one or a few product types and had only limited adjustment possibilities. There was a separate machine for each new type of thread. The blanks had to be inserted manually before each process, which was very time-consuming and prone to errors.

New concept enables adjustable profiles and full automation

Thanks to a new mechanical design and the use of servo drives, the function of the machine has been completely revised. The arrangement of the cuts, which was previously determined by the fixed mechanical guides, now only depends on the parameter set of the servo drives. Only the knife angle must be adjusted manually. But also, for this adjustment an automatic procedure has already been developed and tested for the next update of the machine.

To change the profiles, the appropriate recipe must now be selected on the machine’s control panel. In addition, the profiles can be newly created and edited. In order to be able to check the settings easily, the profile is displayed graphically on the panel. If a parameter is adjusted, the image is dynamically adapted.

After each cut, the thread, which previously always had to be re-inserted, is pulled off a bobbin by an automated infeed and fed into the machine and the cutting process starts again. The thread cut according to the selection is deposited in a box. This way, production is fully automated and employee intervention is only necessary to change the bobbin. Due to the adaptation, the set-up times could be reduced considerably, and the product variance of the individual machines could be increased.

Selection of the profile via control panel, microscope images of the products

Soft encoders guarantee maximum customization possibilities

The software is based on a rotary transfer machine, each with a soft encoder for the main process, the positioning and tensioning of the thread, and the secondary process through which the profile cuts are carried out. This means that not only the speed of the machine is freely adjustable, but also the cutting profiles can be set by the parameter sets as described above. This flexibility makes it possible to use the machine also for the development of new products, which previously had to be created by hand in the laboratory. The machine concept can be transferred to many other applications where simultaneous processing and pull-through movement of the material is required.