Task

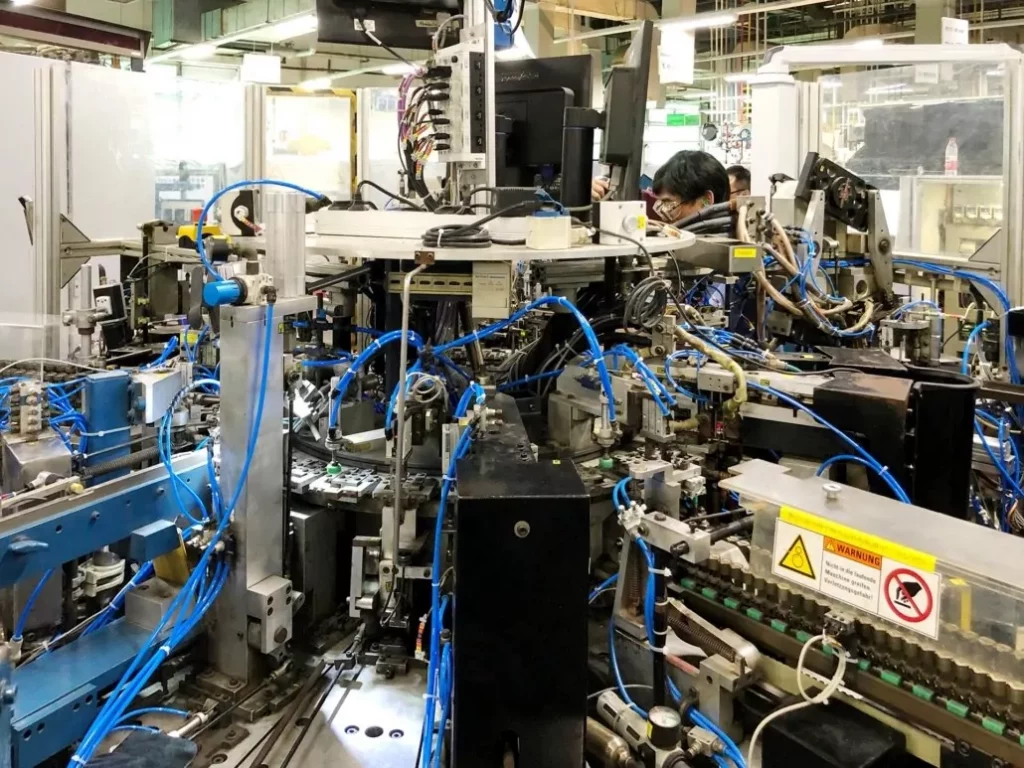

The goal was to modernize one existing plant for the production of halogen bulbs, which is in use in various automobiles. The production plant consisting of a supply as well as a discharge conveyor belt, a rotary machine and various quality assurance units is operated in Songzi (China) and is part of an automated production line. Because the lifetime of the components exceeded and the controller was discontinued, the system should be brought to the newest state of technology.

Engineering and project management

The engineering and production of the components was done in Germany. All finished parts including accessories for modernization were transported to China by air freight. The project management in the preparatory phase was coordinated from Stolberg and continued with the implementation in China.

Electrical modernization

The complete machine installation including control cabinet group and user interfaces should be exchanged. An existing vision system was adapted to the new concept and revised. The product tracking and operational data acquisition was modernized and integrated into the new control cabinet group.

Mechanical modernization

Old pneumatic actuators were replaced by bus-connected valve terminals, the pneumatic installation was renewed.

Software/Visualization

The new software was prepared in Germany and tested in a simulation. In addition, the BDE system was revised, adapted to the new control system and integrated in the infrastructure of the customer. The user interfaces were developed in cooperation with the customer.

Conversion and commissioning

One priority was of course a possible short downtime of the production line. By optimal project planning and preparation we were able to let reconstruction and commissioning phase flow seamlessly into each other, so that the production loss during modernization was reduced to a minimum.

Documentation /Training

On site an operator training was done and an operating manual was prepared. The electrical circuit diagrams were newly made in EPLAN P8.