Improvement of quality assurance through new, automated measuring system

The core ring is a component in the manufacture of a car tire, the incorrect dimension and out-of-roundness affect the durability and stability of the tire and can lead to higher and irregular wear. The device previously used by our customer was not able to reliably record the geometry of the core ring. The aim of the project was therefore the new development of an automated measuring system, which can record and analyze all relevant data of the core ring and can be used for different core ring diameters. The recorded data and results should be forwarded to a higher-level software for consistent quality assurance.

Mechanical and programming challenges

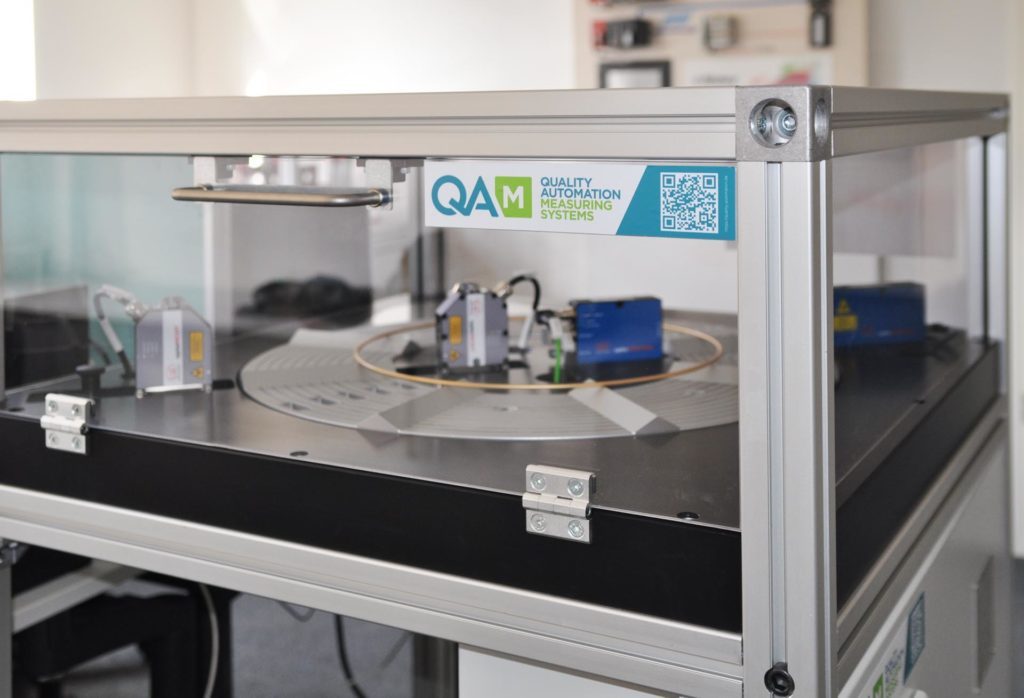

A completely new concept was initially developed for the measuring machine. The balance-free storage and even movement of the core ring through a rotating plate and the simultaneous precise scanning of the geometry posed a particular challenge. To be able to measure the core ring completely in one pass, the measuring machine must move the core ring completely past the sensors. During the rotation, the inner and outer radius and the height, coupled to the current angular position of the turntable, are recorded using high-precision laser triangulation sensors and shading sensors. This results in thousands of measured valuesin a few seconds, the analysis of which turned out to be too complex and computationally intensive for a PLC software due to the amount of data and the complex mathematical iteration process.

High-precision mechanical production and MATLAB integration

Our partner company Hille Engineering GmbH was entrusted with the mechanical question and developed a solution that enables a uniform rotation of the balanced rotating plate and thus the core ring. Quality Automation GmbH took over the electrical design, electrical installation and software development of the system. A Beckhoff drive consisting of a servo motor and gear was used to drive the turntable. The control was implemented on a Beckhoff IPC with Beckhoff TwinCAT 3. A MicroEpsilon laser micrometer for measuring the height and two laser displacement sensors for recording the inner and outer radius were used to scan the core ring with an accuracy of 10 μm. The recorded data points are linked to the position data in the controller and saved as a CSV file. A MATLAB script was developed in parallel to the actual system control, which is started in the process by the control. The script reads in the exported data and takes over the complex calculations of the minimum, medium and maximum radius, the optical diameter, the circumference, the roundness and deformation. The results are stored in various files and read in by the Beckhoff control. The results are clearly displayed to the operator as valuesand as graphics on the panel surface.

Measuring system with connection to quality management software

The developed measuring system forwards the data and results via OPC UA to the higher-level quality management software QDA. By making slight changes to the design and software, the system can also be used to measure concentricity or runout, for example of shafts, spindles and many other components from the automotive, mechanical engineering or medical technology sectors.