Ready for Industry 4.0

As part of a master’s thesis, an existing production plant should be digitally modernized and thus made capable for Industry 4.0. The aim was to draw new conclusions about the performance and possibilities for improvement of the plant through the targeted collection and evaluation of plant-related data.

As a long-term system partner, Quality Automation GmbH relies on the innovative products from Bosch Rexroth even in the area of the Internet of Things and uses the IoT Gateway from Bosch Rexroth for this retrofit.

Internet of Things via gateway

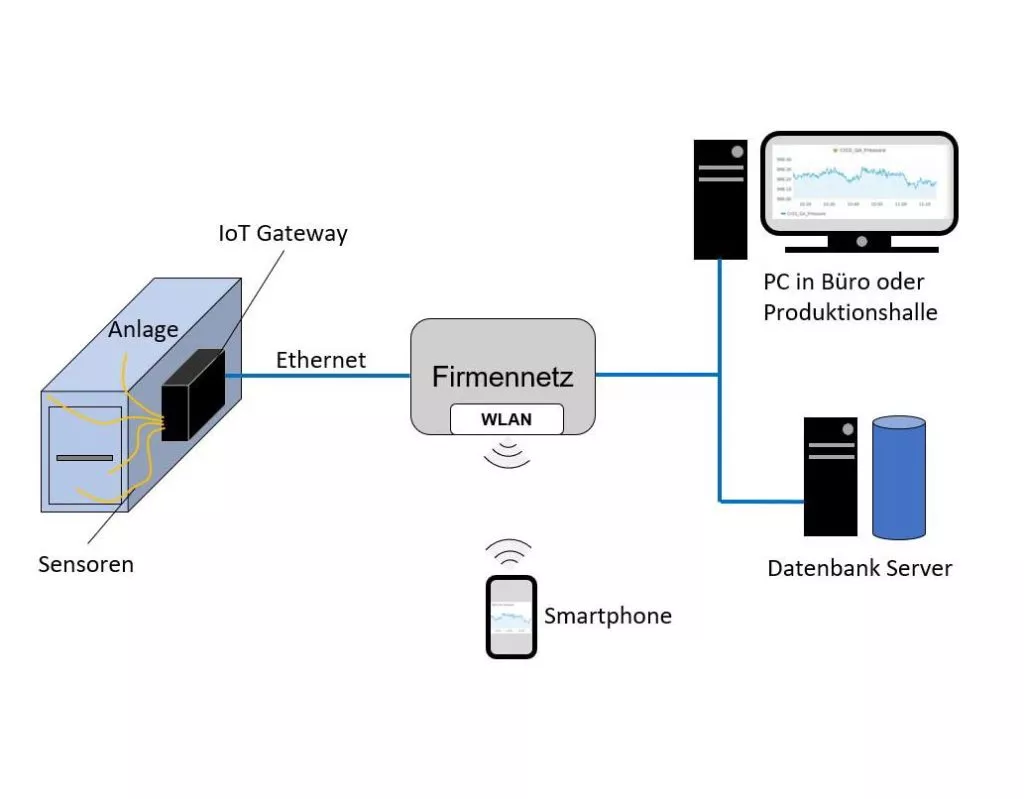

The modernization included the installation of new sensors in order to create transparency about current machine and production data. First of all, it was analyzed which process parameters play a decisive role in optimizing the production and increasing the efficiency of the system. Furthermore, the collected data should be processed and presented visually in the form of graphs, tables and long-term statistics. The IoT Gateway was used as the central connection point between the field and control level, the production plant and the higher-level IT systems.

The IoT Gateway consists of hardware and software, compactly integrated in a small control cabinet, for direct attachment to the system. In addition to the IoT Gateway software, the service IoT Insights for visualization was installed on the existing IPC. Via Ethernet and by means of analog cabling, e.g. temperature, vibration and air pressure sensors, a network analyzer and individual outputs of the PLC are connected to the hardware components of the IoT Gateway. The recorded process and production data are processed in the IoT Gateway software and sent to the higher-level system IoT Insights for data storage and visualization.

Increase in quality and reduction of failures

A complete monitoring of the process data, such as temperature, pressure and vibration, enables a consistently high quality in production and offers completely new possibilities in the area ofpreventive maintenance. The visual representation of the data enables production processes to be tracked and further optimized exactly. There are also options for issuing warning messages in good time when process valuesare exceeded. By connecting to the internal company network, it is possible to monitor the process data from various end devices using a browser.