Target

In the scope of a master exam at the technical college in Aachen a test bench for force-displacement measurements was built up at the company Quality Automation. The project should provide a basis for investigation regarding the impact in case that materials are loaded with forces. Maximal velocities should be detected in which case a force measurement can take place.

In the today’s manufacturing often processes are applied in which different materials are treated under influence of forces, e. g. connecting processes, material welding under pressure or endurance testing.

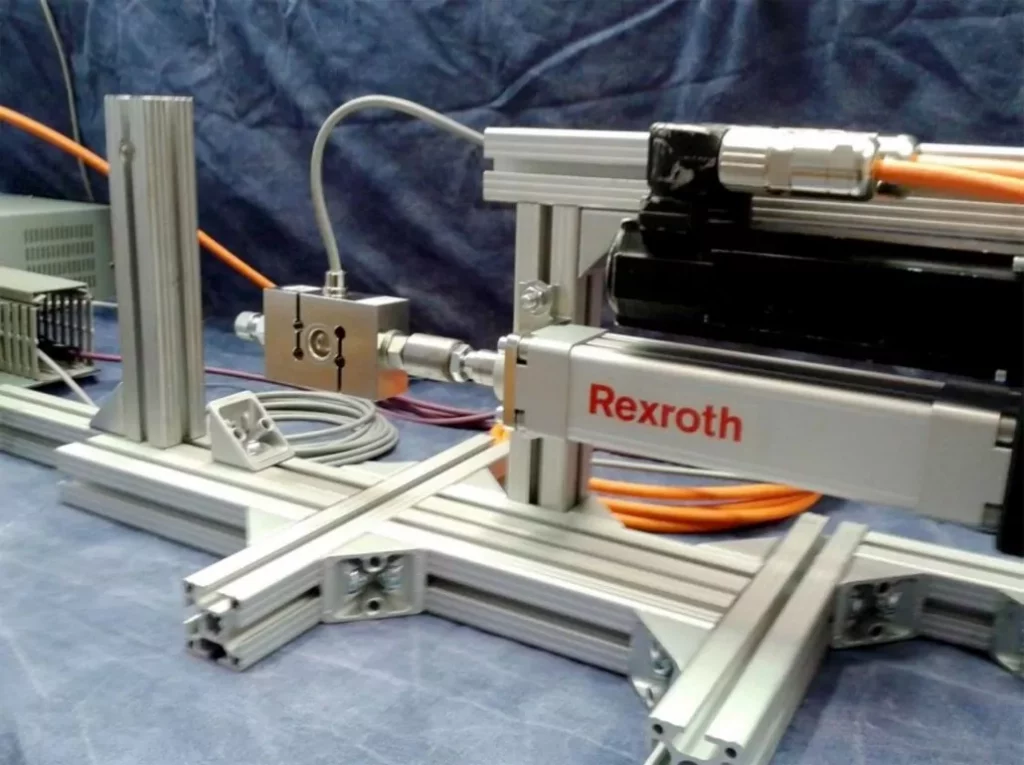

The test bench

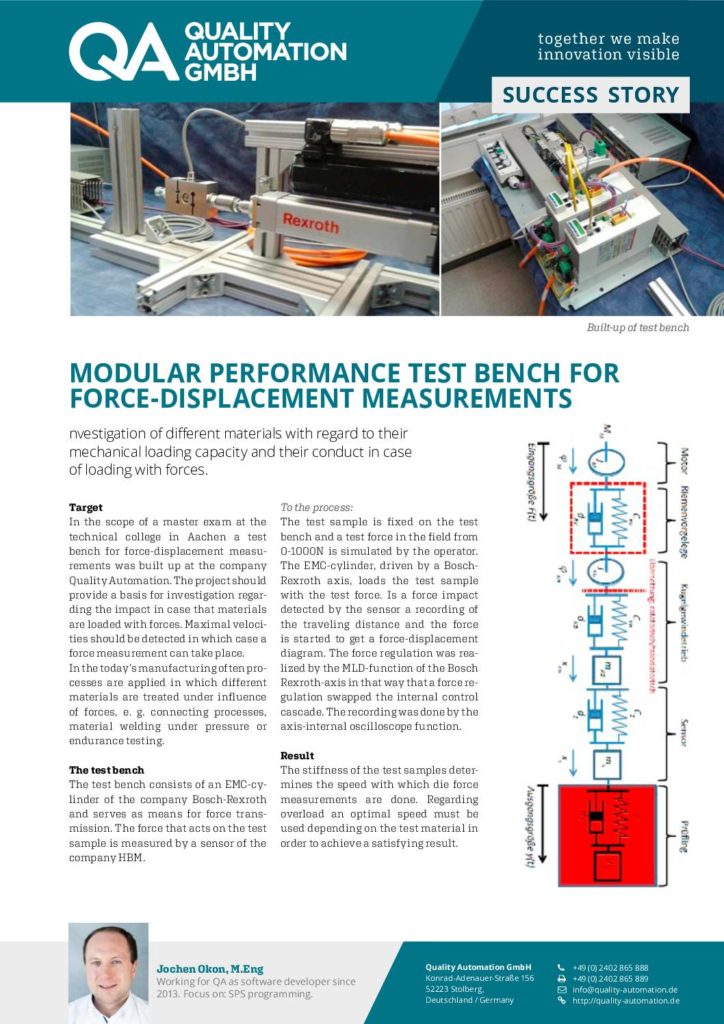

The test bench consists of an EMC-cylinder of the company Bosch-Rexroth and serves as means for force transmission. The force that acts on the test sample is measured by a sensor of the company HBM.

To the process: The test sample is fixed on the test bench and a test force in the field from 0–1000N is simulated by the operator. The EMC-cylinder, driven by a Bosch-Rexroth axis, loads the test sample with the test force. Is a force impact detected by the sensor a recording of the traveling distance and the force is started to get a force-displacement diagram. The force regulation was realized by the MLD-function of the Bosch Rexroth-axis in that way that a force regulation swapped the internal control cascade. The recording was done by the axis-internal oscilloscope function.

Result

The stiffness of the test samples determines the speed with which die force measurements are done. Regarding overload an optimal speed must be used depending on the test material in order to achieve a satisfying result.