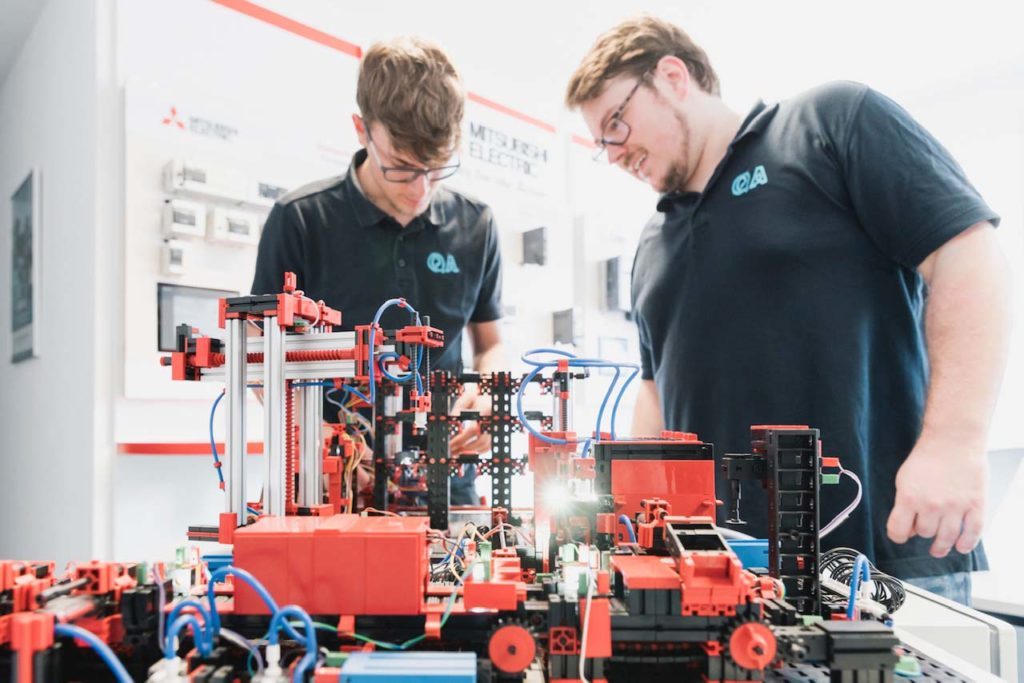

For some time now, QA has been using a Fischertechnik-model for factory simulation. This combination of different stations, controlled by a Siemens Simatic S7-200, is used by trainees, interns and Bachelor or Master students to realistically model complex processes.

As QA it is important to us that our trainees, interns or students can work in a practical way and thereby gain important experience. Only by applying and implementing do you learn to find solutions and master challenges on your own,” explains Managing Director Andreas Fritz.

The factory simulation consists of the models sorting line with color recognition, multi-machining station with kiln, automated high-bay warehouse and a vacuum suction gripper. With these stations, a closed material cycle is possible. The workpieces are retrieved from the high-bay warehouse, processed in the machining station, then sorted by color in the sorting system and then returned to the high-bay warehouse.

In the course of a bachelor thesis, the software was recently revised and further developed, so that many new functionalities have been added. It is now possible, for example, to select via the Simatic HMI panel the exact sequence in which the differently colored workpieces are to be retrieved and returned to storage.

To give you an insight into our fish technology model, we have filmed a machining cycle from different angles and edited it into a short video.

We hope you enjoy watching it.