Measuring system with data bank

An essential part of the job was to realize a simple measuring system with an order administration and a data bank. The orders are entered in the data bank by the workshop master in the office. The measuring system is a simple manual measuring equipment that checks bucked profiles regarding their length. It is located in the workshop where it is connected with the PC in the office via internal network. The measuring values are saved in a data bank and a measuring protocol can be printed out by the workshop master. If there is a profile out of tolerance it is indicated by a signal lamp.

Main focus: simple, intuitive operating

They chose a Panel PC with touch screen of Siemens and an I/O card of National Instruments as operating equipment. The PC communicates with the existing measuring equipment via serial interface. The I/O card is used to read in and steer buttons and lamps. The software was programmed with LabView. In order to equip the simple and intuitive operating with a motivating extra for the staff the login and the entering of orders are realized by pictures.

Concepts that motivate

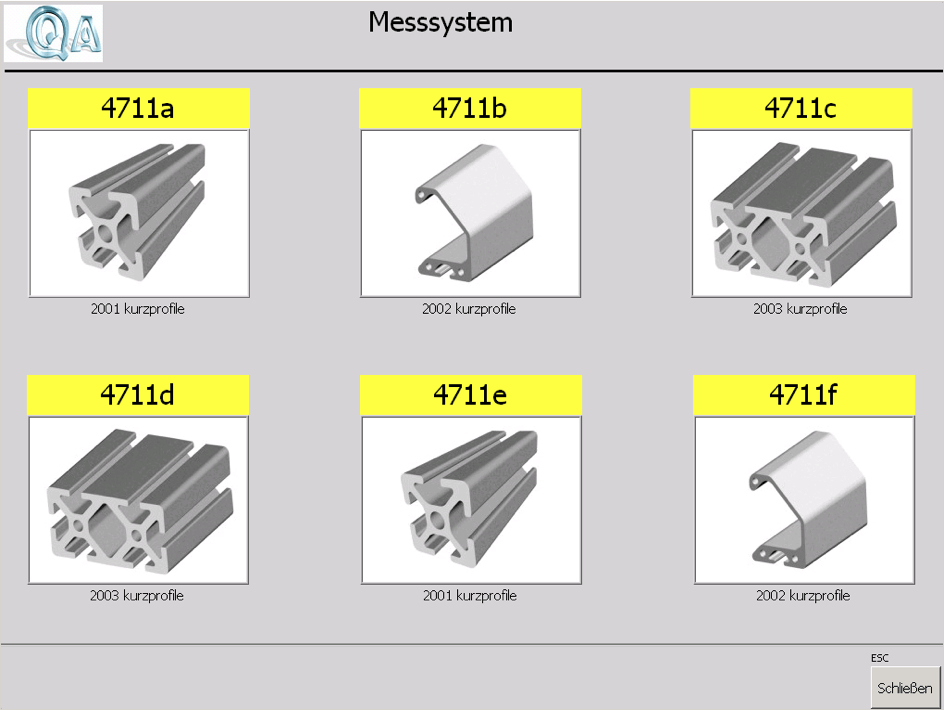

All members that work with the measuring system are registered on the starting page with name and photo. When the staff member presses on the photo he will be logged into the system and in the background the software registered the name in the data bank. The second screen page shows the orders with photos and texts of the objects that have to be checked. The selection of the orders is again done with the pressing of the corresponding photo. By that the data of the order are automatically loaded from the data bank. By the control via photos and touch screen, all staff members are leaded through the menu in a simple and motivating way.

An individual solution for our customers is a matter of course for us.