Automatic thread inspection

The company KORDT GmbH & Co. KG offers with its module TRANSICORD an automatic thread testing unit, which performs a thread test by means of torque measurement and monitoring. Among other things, the thread depth and continuity are checked. The control of this unit was implemented with Bosch-Rexroth components by Quality Automation GmbH. For this purpose, a threaded pin attached to the linear axis is moved in the direction of the thread at a threading speed, screwed in and then, at a higher inspection speed, the inspection program is run. The operator then receives the result of the test. The thread testing unit can be used for different thread sizes.

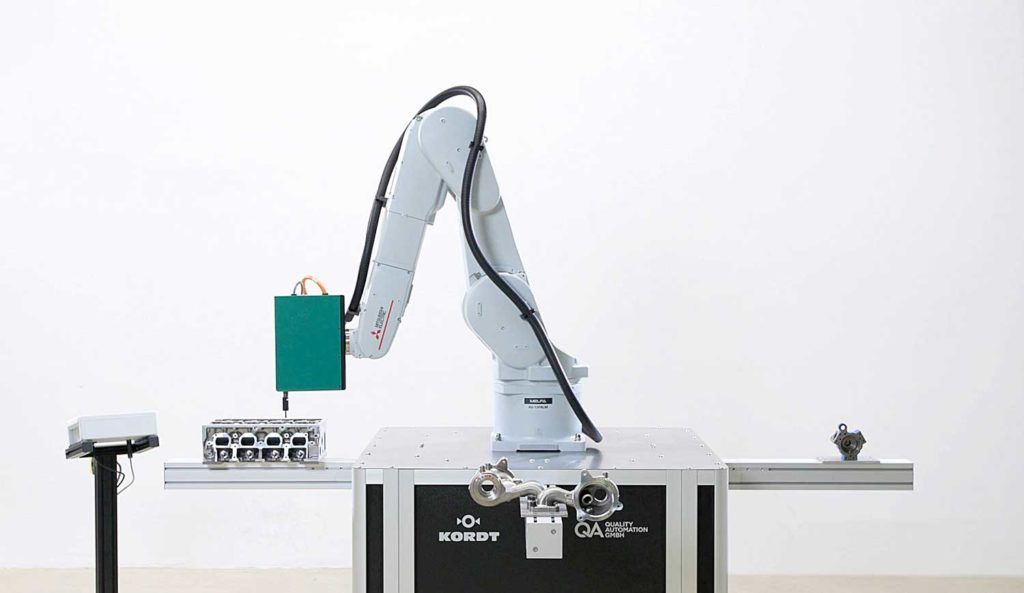

The robotic automation

With its TRANSICORD module, the company KORDT GmbH & Co. KG introduced the world’s first fully automatic thread testing unit as early as 1966. With the current generation of thread testing units, the thread testing of large components, which was previously carried out manually, is now also automated. To make this process more effective and faster, Quality Automation GmbH has developed a robot program that now performs thread inspection automatically. Using a 6-axis robot of the type RV-13FRLM from Mitsubishi Electric, we position the inspection unit over the thread with an accuracy of ten micrometers. This also maintains an exact angle, which is necessary to ensure error-free testing. The company KORDT GmbH & Co. KG has created a great video of the thread inspection process performed by the robot. Get your own impression of the process and: Have fun watching!You are currently viewing a placeholder content from YouTube. To access the actual content, click the button below. Please note that doing so will share data with third-party providers.

More Information