ERP system and steel construction at the highest level

The company Müller & Sohn from Kall, in the Eifel region close to us, is already a long-standing user of our customized ERP system QAenterprise. As part of our close and good cooperation, we have now successfully implemented a digitalization project in the manufacturing workshop. The newly developed software works here independently of the already existing QAenterprise.

The internationally active steel construction specialist Müller & Sohn develops individual designs for its customers. The services range from static calculations to on-time realization and final acceptance. Companies from the food and pharmaceutical industries as well as from general plant construction rely on the know-how and performance of the specialized experts of the fifth-generation family business.

Development of a new software solution

Before the digitization realized by Quality Automation GmbH, all CAD drawings had to be printed out so that they could be worked with in the workshop. This resulted in increased costs, time and resources. The goal was to digitize this process and thus make it more effective and modern.

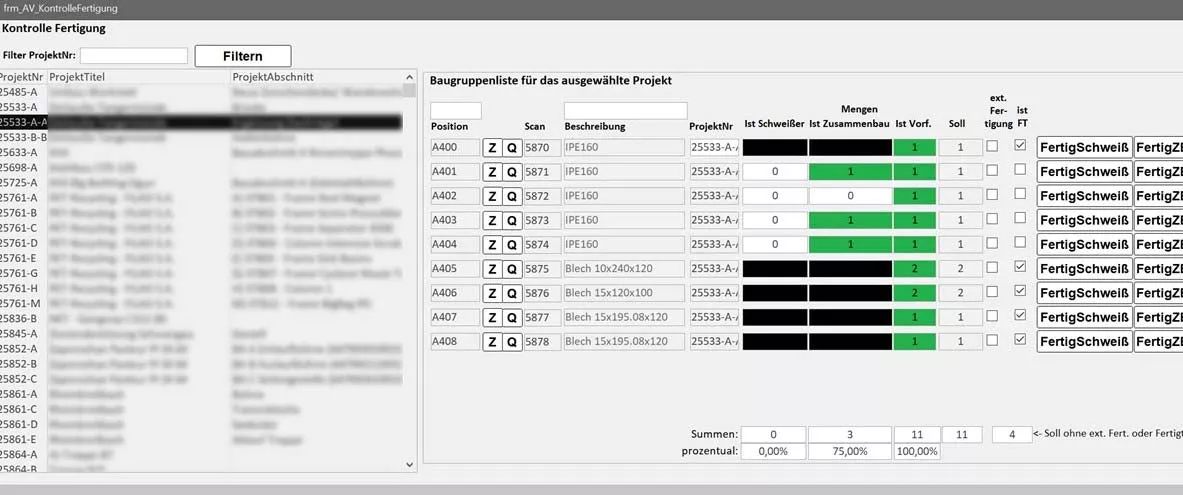

Like QA Enterprise, the digital manufacturing management software is based on Microsoft Access and can be integrated into the ERP system if desired. However, the flexible standalone solution that we have implemented here is by no means disadvantageous and integration is also possible at a later date at any time. The software developed from scratch by Quality Automation GmbH has resulted in a perfect application tailored to the customer’s needs, which can be extended and adapted at any time if required.

Traceability through digitization of production

With the new manufacturing management software, a QR code is generated at the beginning of the work process and attached to the respective component. In the workshop, this QR code can be read with a hand-held scanner and the CAD drawing appears on an attached screen. After completion, this must be confirmed in the software and the construction of a new product can begin. Confirmation from manufacturing has the advantage that the manufacturing status of each component, across the various process steps, can now be tracked and recorded live.

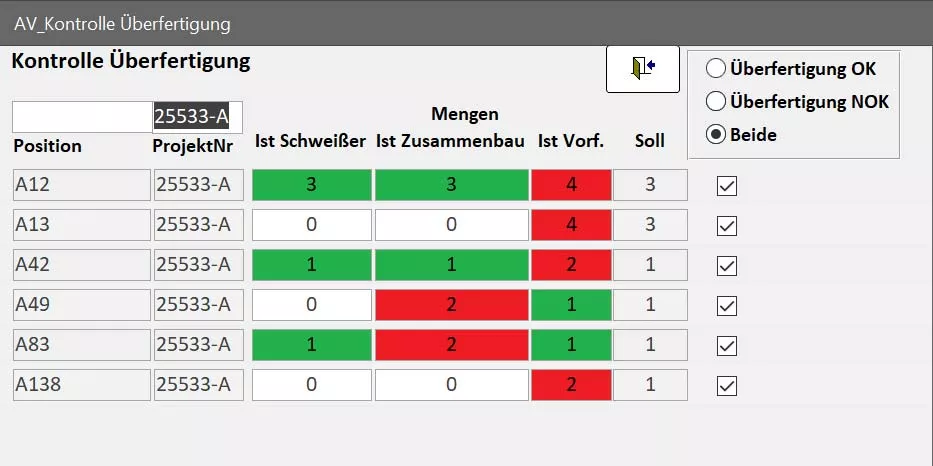

The new manufacturing management software includes a system control with user and rights management. This allows different users to be granted different rights. As already described, digital QR codes are generated and printed from the software. In clearly arranged forms, the manufacturing status of the components is displayed during the entire production and can also be managed from there.

A wide range of statistics on assemblies, projects and any product characteristics can be displayed and analyzed over a desired period of time to continuously optimize production.

The employees in the workshop also have the option to enter comments on the production of the component. In this way, special features or problems can be recorded and traced over a long period of time. Every night, a report is automatically stored on the in-house server for documentation purposes. This report, with freely definable content, contributes to the traceability of production and thus to compliance with certain standards.

Extensions of the application

A new extension is already in the pipeline: In the future, the management of shipping and inventory will also be regulated via the new digital production management. We look forward to the successful implementation of this new challenge.