Our close partner Fibraworks GmbH has been nominated as a finalist for the JEC Innovation Award 2022 in the Equipment and Machinery category with its patented process, Fibraforce technology. We are delighted that we were able to contribute with our control technology know-how to the production of energy- and resource-efficient products for sustainable lightweight construction suitable for mass production.

Our close partner Fibraworks GmbH has been nominated as a finalist for the JEC Innovation Award 2022 in the Equipment and Machinery category with its patented process, Fibraforce technology. We are delighted that we were able to contribute with our control technology know-how to the production of energy- and resource-efficient products for sustainable lightweight construction suitable for mass production.

The JEC World and the Innovation Awards

JEC World is the global trade show for composites and their applications. Held this year in Paris from May 3 to 5, it is the industry’s leading event, bringing together all the key players under the banner of innovation, business and networking. JEC World delights with hundreds of product launches, award ceremonies, startup competitions, conferences and live product demonstrations.

Each year, the trade show honors the world’s most innovative composite projects and solutions. Launched in 1988, this innovation competition pursues the goals of identifying, promoting and honoring the world’s most forward-looking composite solutions and promotes the development of the composites industry.

The Fibraforce technology

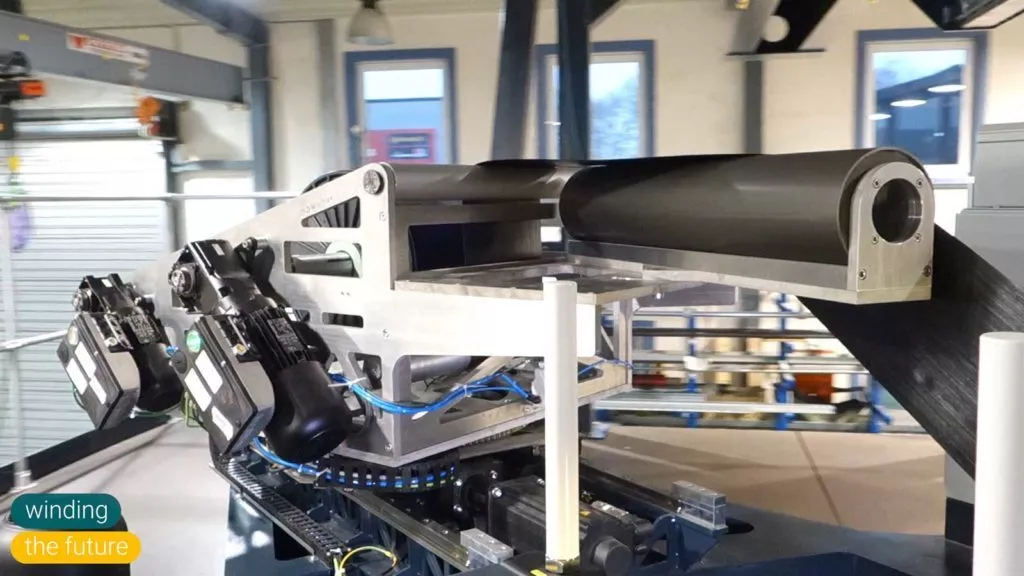

Lightweight construction is a key technology for conserving resources, but often involves complex processes and high costs. With its patented Fibraforce technology, Fibraworks GmbH aims to revolutionize the mass production of customized multiaxial thermoplastic laminates. The high-tech startup in the field of thermoplastic composites, based in Aachen, Germany, has also set itself the task of using resources more efficiently, reducing energy consumption in production and making its products recyclable. With the company motto Winding the Future, contributing to a greener future is part of the corporate vision.

Fibraforce technology describes an innovative winding process that can produce optimized multi-layer, multi-directional composite half-molds tailored directly to the customer’s application and needs. The continuous manufacturing technology replaces conventional, costly and time-consuming manual or discontinuous manufacturing technologies with an ultra-fast, cost-effective and precise production process.

The aim of Fibraworks’ patented innovation is to make lightweight construction with composite materials widely available. It is aimed at all industries that benefit from lighter, stronger and more durable parts. By using composites with optimized fiber alignment, a lot of material and weight can be saved.

Innovative control concept from QA

Due to the special features of the plant, Quality Automation GmbH has developed a control and drive concept at the highest level, specially tailored to the conditions. The plant consists of a rotating platform, which contains two unwinders that also rotate. A stationary control cabinet next to the plant communicates via radio technology with a second control cabinet on the rotating unwinding platform, which is supplied with mains voltage via a slip ring. The rotating control cabinet controls several drives, which are synchronized with each other using electronic cams. The two control cabinets have antennas for communicating with each other and the safety technology is also implemented with PROFIsafe via WLAN.