You are currently viewing a placeholder content from YouTube. To access the actual content, click the button below. Please note that doing so will share data with third-party providers.

More InformationSimulation and control

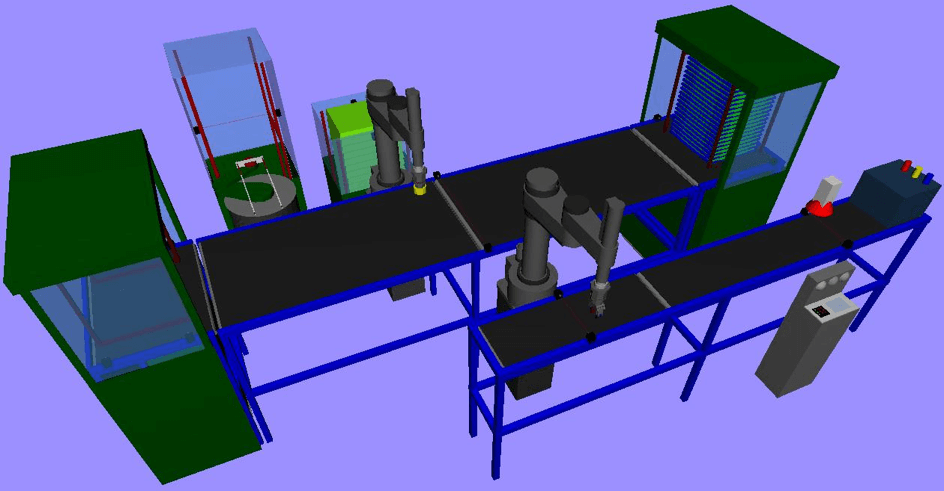

The advantage of simulation software is the possibility to test real applications in a software environment on your local PC. This helps to reduce the downtime of the plant and offers several opportunities when debugging the PLC-software. At Quality Automation we provide innovative software solutions, and therefore we constructed a test-application on which we can validate and verify our PLC-software. The used simulation-tool „virtuos“ is provided by the company of ISG — Industrielle Steuerungssoftware GmbH — Stuttgart. With this tool one can create a simulation and a visualization of the application – the process can be viewed as a 3D-modell.

The assembly line

As application we simulated an automatic assembly line. Process: Several different components are placed on a workpiece carrier. After that placement the carrier is encapsulated with a housing. The components and the carrier are located in storages and can be integrated into the process by conveyor belts. The component placement and the encapsulation are performed by SCARA-Robots. During a process cycle the workpiece carriers are placed on transport carriers and after the encapsulation they are separated from each other. That separation and the storage process are executed by additional SCARA-Robots. The PLC-System “TwinCAT” of the Beckhoff company was used to control the simulation.

Hardware in the loop

Because of the real-time capability of virtuos, it is possible to create a real image of the manufacturing process. The PLC-programs can be tested on the simulation, failures can be found an eliminated even before the real commissioning. In this project, we were able to successfully validate and verify our PLC-programs on the simulation.