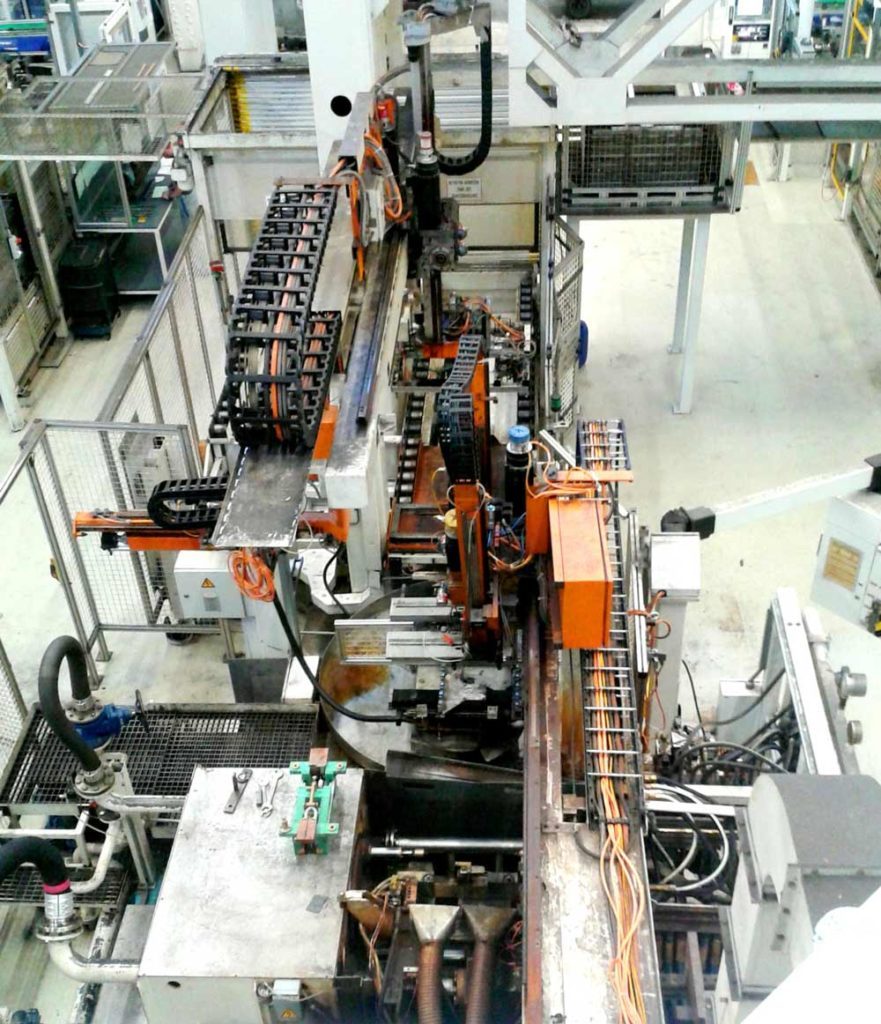

Plant general view before modernization.

Definition of a project

The technology of the plant was obsolete and the spare parts are not available. The target was the complete modernization of the total plant for hardening of drive shafts in shortest downtimes.

Mechanical modernization

The equipment was deconstructed in all single parts and all wear parts of the plant (journals, connectors, sealing gaskets, gear rings and guiding shafts) were replaced. By using new cylinders, valves and supply units the pneumatic and hydraulic systems were modernized all around. A higher plant dynamic was achieved by using servo drives.

High voltage and converter

The high voltage transformer as well as the converter plant of the hardening processor in transistor technology were replaced. The existing supply racks were revised, the water cooling system was modernized.

Electrical modernization

It becomes necessary to replace the electrical plant installation including switchboard cabinet, operating, sensor technology and cabling completely. All safety functions were realized by the use of safety control and corresponding drive controllers. Via industrial PC as well as and mobile panels operating was realized.

Process optimization and Visualization

Via visualization tailored to the plant an operator guided control as well as an optimal process supervision of all plant conditions were realized.

CE and documentation

Based on the new conformity declaration of the plant it becomes necessary to prepare an extensive documentation including risk evaluation according to appendix VII of the EC machinery directive.