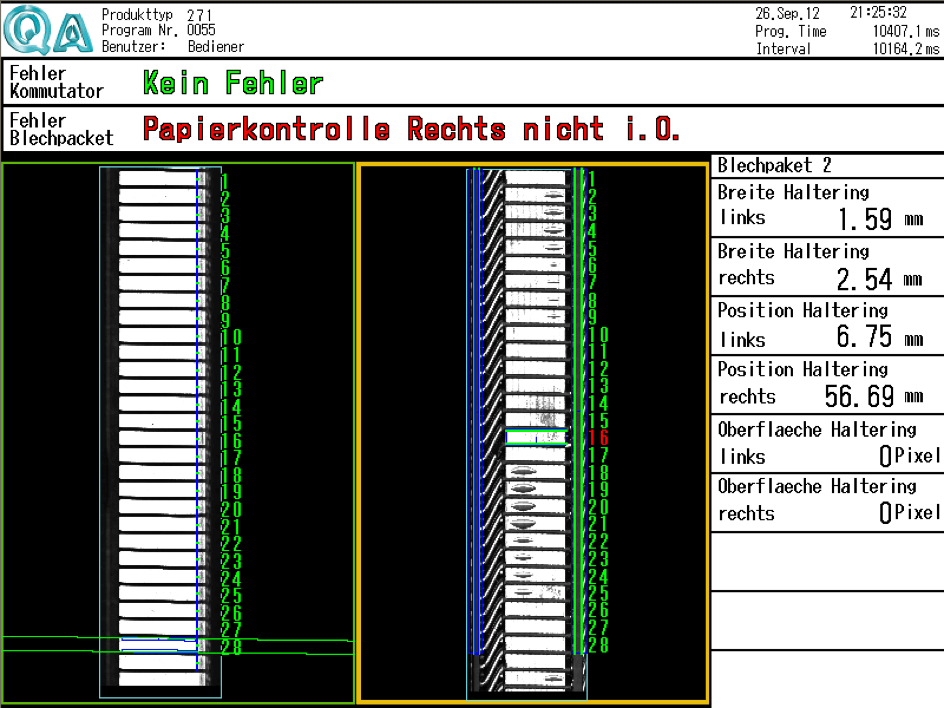

Left: starting image, right: zoom image.

Surface analysis

Many quality criteria are checked by optical control of employees. These checks are very exhausting for the staff and unfortunately they are fault-prone. A possibility to reduce faults is the control by means of an industrial image processing. In the starter production of the company Robert Bosch GmbH near Hildesheim the armatures are checked regarding a plurality of optical features during the end control. In case of cylindrical objects like an armature a line camera generating a rectangular image of a bended surface is most suitable for that. The XG-series of the company Keyence offers a very powerful consolidated system for that. In an easy way it becomes possible to incorporate a line camera into an industrial surrounding.

Structured operator guidance

The company Quality Automation GmbH uses the various scopes for design of the XG series of Keyence to create a structured operator guidance. This was linked to an intelligent programmed algorithm for fault finding, also realized by the company Quality Automation GmbH. The various required quality features are detected and supervised safely in this way. All parameters being important for the application can be adjusted by the staff directly at the equipment, an extensive knowledge regarding image processing is not necessary for the staff. The parameters are explained in a detailed documentation. Owing to the extensive Vision tools of the Keyence XG-series the programming of difficult failure features is simplified.

Image recording control via servo motor

A feature of this application is the image triggering via servo motor. The Keyence XG-series offers the possibility to trigger the line camera via an encoder signal. The IndraDrive of Bosch Rexroth has an output device to pass the internal encoder signal. By that an image recording can even be created when accelerating or in case of different drives.

Complex image processing, easy solution

A line camera application was up to now always a very complex task and makes an effective realization almost impossible. By using the XG-series of Keyence the complexity of the project realization will be reduced to the essential features. The provided hardware is attuned at best on each other and only a program technical implementation becomes necessary.