Digitalization, artificial intelligence and data connectivity: The future of a company

In a world that is rapidly digitizing, it is crucial for small and medium-sized enterprises (SMEs) to keep pace in order to remain competitive. Digitalization is no longer just a buzzword, but a necessity that can make the difference between a company’s success and failure. In this context, artificial intelligence (AI) and effective data connectivity play a central role. But how can you, as an entrepreneur, ensure that you exploit the full potential of your investment data?

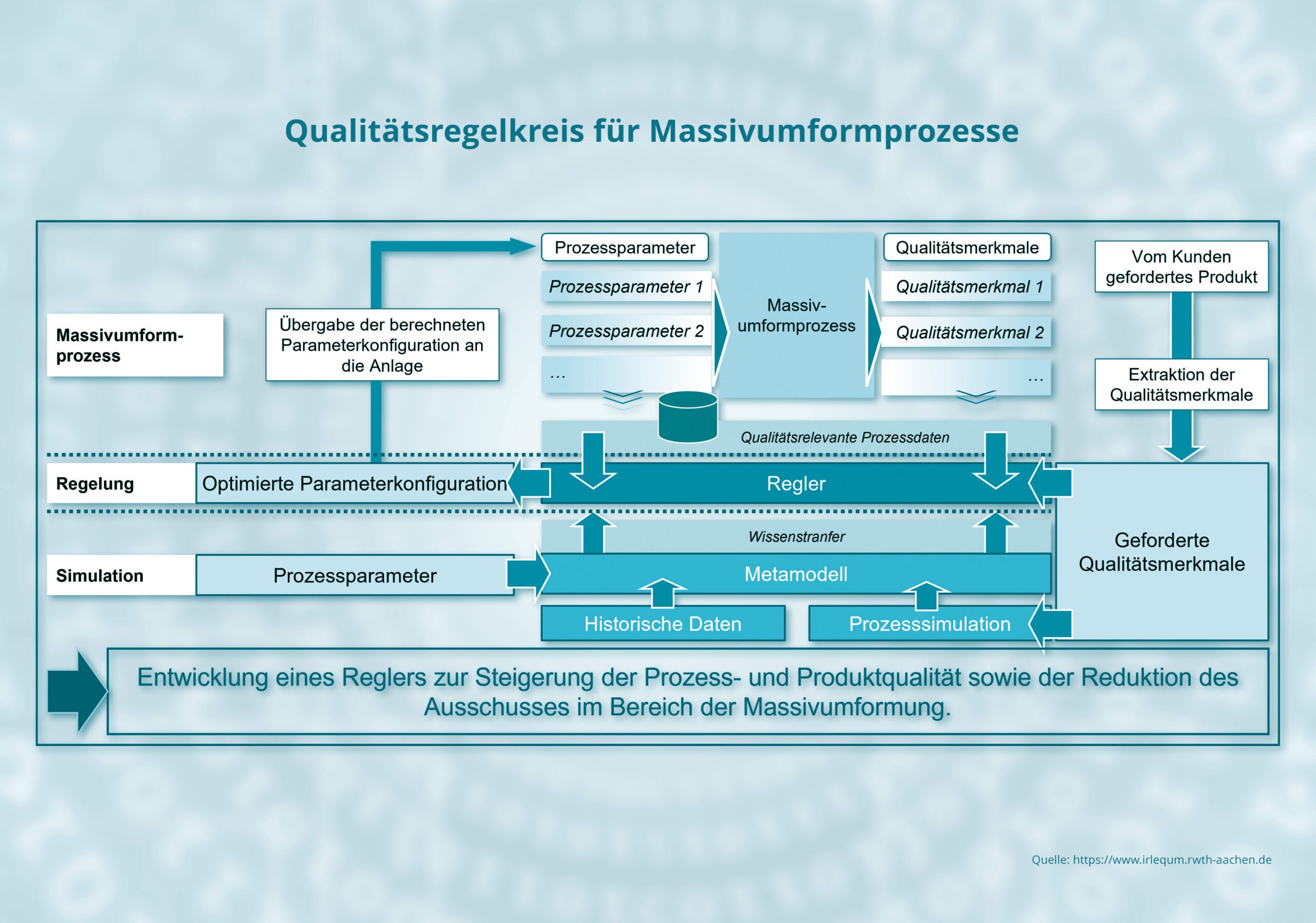

As a participant in the IRLeQuM research project, we collaborated with chairs at RWTH Aachen University and selected application companies to research a new method for increasing process and product quality. The focus was on reducing scrap in the area of forging by implementing controllers based on reinforcement learning (RL) and transfer learning (TL) in the quality control loops of forging processes.

Framework for data aggregation

Under the leadership of QA, the project team has developed a flexible, company-independent framework for creating an efficient IT infrastructure. This framework enables the aggregation and analysis of various data sources and formats and is specially designed to ensure fast and targeted integration into production environments. As a result, the potential of modern evaluation algorithms can be fully exploited.

The framework provides a comprehensive guide to integrating various data sources into a company’s IT landscape. It describes the essential steps and components for recording process and plant data and preparing it for higher-level systems or services. It serves as an orientation and planning aid and may need to be adapted to the specific circumstances of a company. Although the framework is primarily optimized for the integration of an AI controller, it can also be easily transferred to other areas of application such as data aggregation for (AI) monitoring systems.

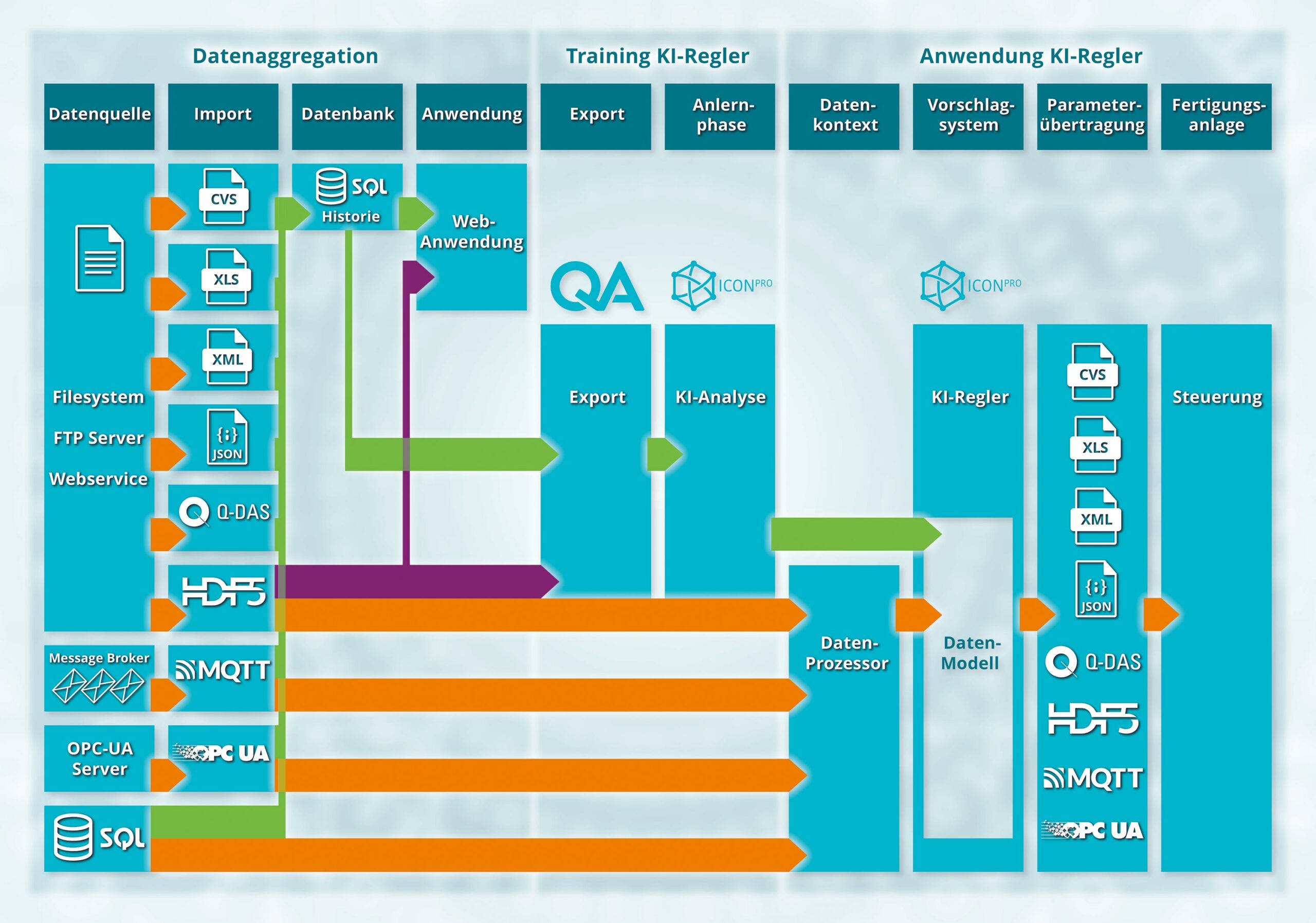

The first section of the framework highlights the various data sources that arise in a manufacturing company and their import into a central database. This includes process data directly from the plant control system, CSV files from testing and measuring systems as well as manually entered data. Before production, data on orders, customers, material certificates, tools or lubricants can be generated. During production, machine and environmental data is recorded and after production is complete, measurements provide the basis for quality control.

This data is available in various formats, for example in databases, as OPC UA variables or in documents that can be loaded from file, FTP or HTTP servers. Each data source requires a specific import software component that converts the data into a normalized format in an SQL database. The software solutions are based on a modular system whose components can be adapted to the specific requirements of the company and its data formats through configuration or software changes.

Optionally, the normalized data can be made available to employees and other software systems via a web application. The data is presented in clear tables and graphs or made available to a live monitoring system for process monitoring. The normalized data is exported to a CSV file and made available for downstream data analysis in a structured and standardized format. As part of the data analysis, correlations between process and product characteristics are identified and saved in a data model.

Real-time data (OPC-UA and MQTT) is enriched with the data previously imported and stored in the SQL database in the data processor and fed to an AI controller. The AI controller can use the data model to generate process-optimizing suggestions based on the product, environmental and measurement data. The calculated parameters of the AI controller are transferred directly to the system control or displayed to the system operator via a suggestion system so that they can set the system optimally based on the data determined and their experience.

AI.ready with QA

Thanks to the collaboration between our experts in automation technology and our application development department, we can provide you with decisive competitive advantages through highly professional data mining, taking into account your process expertise and experience. With AI.ready, we work with you to develop a potential analysis from which you can derive the benefits of AI software and also see which steps are required for successful implementation. AI.ready begins with an analysis and review of your existing data. Which data is relevant to the process and where are parameters still missing? It is often possible to derive easily implementable improvement measures at this point.

We can collect missing data either by installing additional sensors or by expanding the machine control system and integrating an OPC UA server and storing it in databases. Using importers specially developed by QA, we implement interfaces between your various data sources and the AI software, or simply put: “We bring your data to the AI.”

But our service doesn’t end there. Of course, you also want to be able to view the data analyzed by AI. The application department at Quality Automation GmbH specializes in precisely this requirement. Monitor all your system parameters using modern web interfaces that display limit values, warnings and push notifications through informative visualizations. On request, we can send the AI decisions directly to the control system to close the fully automated control loop.

Do you already have software or an application that is outdated or no longer offers the desired functionalities? Here too, you can benefit from the knowledge of our experienced software developers. We will analyze your existing software on site and offer you various options for restoring it to a maintainable and modern state.

Download Flyer KI.ready

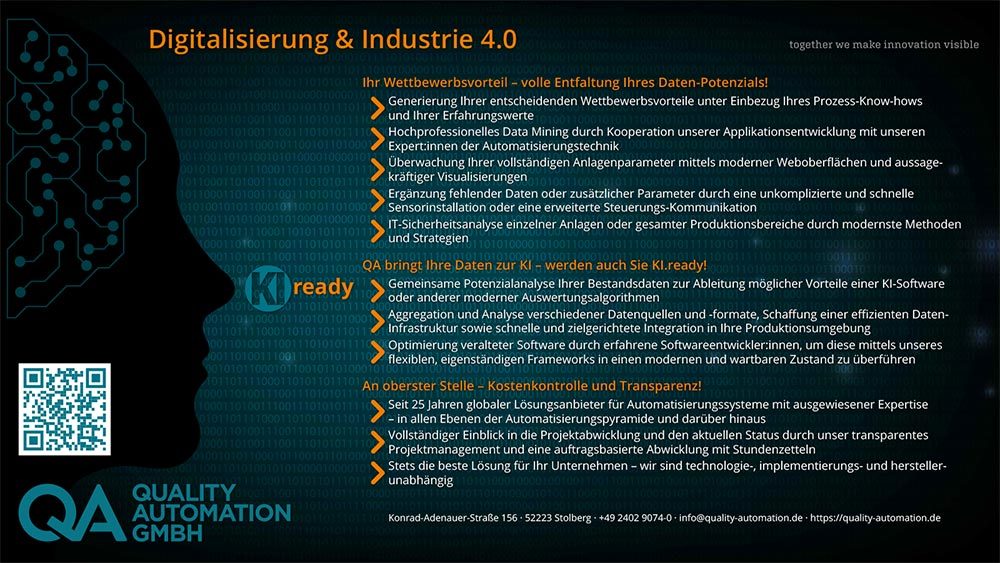

Are you and your company ready for the future? With KI.ready, you can unleash your full data potential and generate decisive competitive advantages. Read our flyer to find out what added value AI.ready from Quality Automation GmbH can bring you.