QAenterprise.de goes online

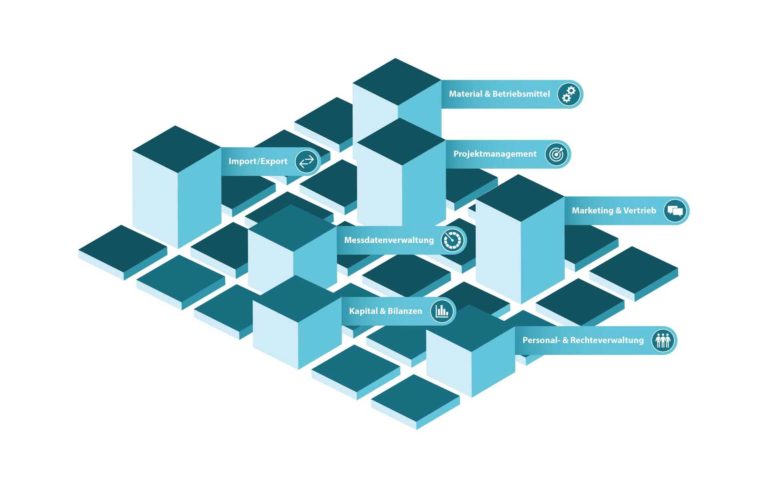

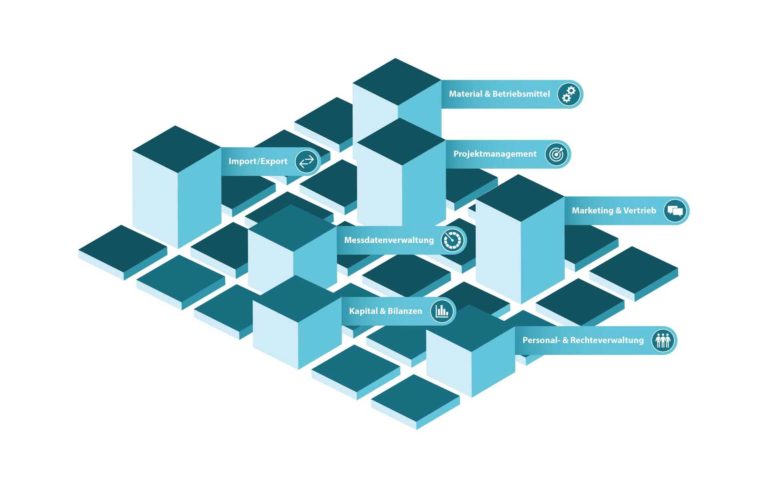

Individual functions of the modular ERP system of Quality Automation GmbH can now be accessed browser-based from various end devices such as PC, smartphone or tablet.

Services Digitalisation & Industry 4.0 Data analysis

Services Digitalisation & Industry 4.0 Data analysis

Quality Automation GmbH successfully develops complex data analysis software tailored to your individual process requirements. Of course, we are also happy to configure or expand existing data analysis systems such as MES or SCADA systems.

Do you want to go digital in the future? Do you want to finally extract added value from your data and visualize processes better? Contact us and together we will take you on the path towards Industry 4.0.

Collecting and storing process or machine data is important and a first step. But you also want to visualize and evaluate your data afterwards.

To this end, we develop complex data analysis software on an order basis, tailored to your individual process requirements and the available data. We are also happy to configure or expand existing data analysis systems such as MES or SCADA systems.

We prepare your data based on your processes and present it to your team in tables, diagrams, graphs and key figures in a clear format for day-to-day work. This enables you to identify previously unknown technical correlations and to further analyze and optimize your production.

In addition to the manual analysis of data, we also support artificial intelligence methods, which are becoming increasingly important, especially for very large volumes of data. Here, we use common frameworks and/or work closely with AI experts, the latter in our interface function between process and AI.

If important measured values for analysis are missing, Quality Automation GmbH can retrofit them with sensors or interfaces.

We make the visualization conveniently available to you via a web application on your servers so that it can be accessed from any end device without pre-installation.

The installation can take place both locally on your servers and with various cloud service providers.

The integration of an application into your IT infrastructure is always carried out in close cooperation with your IT department, but can also be fully managed by us on request.

Once the data has been analyzed, the findings should also be utilized. Quality Automation GmbH provides the necessary expertise for this, e.g. to bring control parameters back into the control system and thus also benefit from the analysis results in the production process.

Of course, it is also possible to prepare key figures for reporting and/or monitoring, e.g. as PDF reports or error messages via e-mail.

You can find a current example of software development in our reference projects:

Individual functions of the modular ERP system of Quality Automation GmbH can now be accessed browser-based from various end devices such as PC, smartphone or tablet.

Create intelligent and networked production and pave your way towards Industry 4.0 and IoT.

You finally want to have order on your servers? Let’s go the way towards Industrie 4.0 together.

We develop software for web-based applications and databases – individually tailored to you!

We carry out comprehensive IT security analyses of your industrial plants and systems.