Machine connectivity

Create intelligent and networked production and pave your way towards Industry 4.0 and IoT.

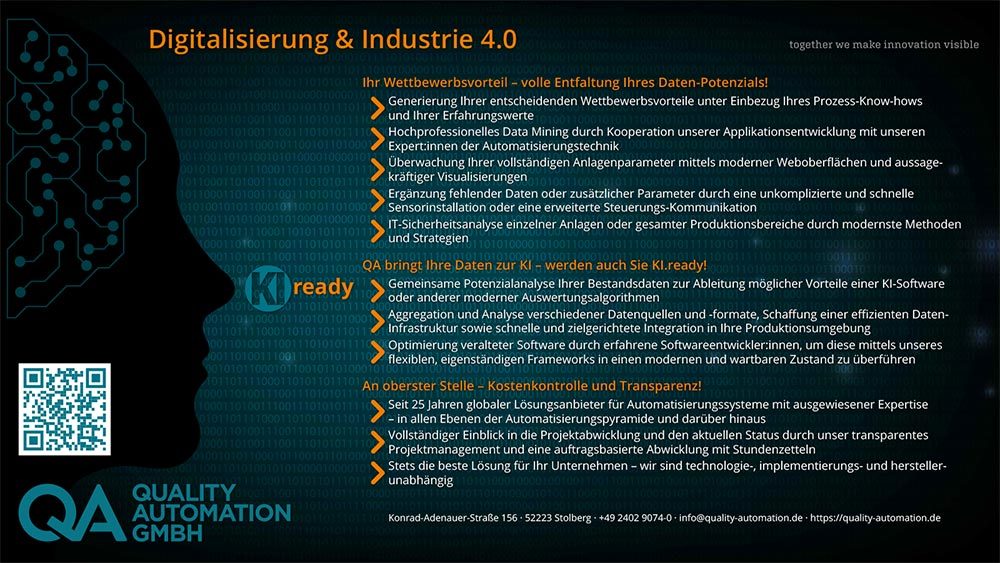

Services Digitalisation & Industry 4.0

Services Digitalisation & Industry 4.0

The integration of industrial production with modern information and communication technology offers your company enormous potential. The reduction of downtimes for your machines, the elimination of interfaces within production and reduced set-up times are just a few examples of the optimization of your entire value chain that can be achieved through Industry 4.0 projects.

Quality Automation GmbH, based in Stolberg near Aachen, stands for global expertise and specialist knowledge in automation technology—from the foundation to the peak of the automation pyramid and beyond. Rely on our experienced team for your Industry 4.0 project, ensuring tailored solutions with full cost control and maximum result transparency. All created documents and software solutions become your full property.

For 25 years, we have applied our expertise to enable seamless communication between diverse systems, supporting customers from various industries in their digital transformation. We facilitate end-to-end networking of the value chain while ensuring compliance with OT and IT security objectives.

From local software applications that replace manual data exchange to complex cloud-based MES systems—we implement every project. Our technology-, implementation-, and vendor-independent approach ensures we always deliver the best solution for your business.

Thanks to the collaboration between our experts in automation technology and our application development department, we can provide you with decisive competitive advantages through highly professional data mining, taking into account your process expertise and experience. With AI.ready, we work with you to develop a potential analysis from which you can derive the benefits of AI software and also see which steps are required for successful implementation. AI.ready begins with an analysis and review of your existing data. Which data is relevant to the process and where are parameters still missing? It is often possible to derive easily implementable improvement measures at this point.

We can collect missing data either by installing additional sensors or by expanding the machine control system and integrating an OPC UA server and storing it in databases. Using importers specially developed by QA, we implement interfaces between your various data sources and the AI software, or simply put: “We bring your data to the AI.”

But our service doesn’t end there. Of course, you also want to be able to view the data analyzed by AI. The application department at Quality Automation GmbH specializes in precisely this requirement. Monitor all your system parameters using modern web interfaces that display limit values, warnings and push notifications through informative visualizations. On request, we can send the AI decisions directly to the control system to close the fully automated control loop.

Do you already have software or an application that is outdated or no longer offers the desired functionalities? Here too, you can benefit from the knowledge of our experienced software developers. We will analyze your existing software on site and offer you various options for restoring it to a maintainable and modern state.

Are you and your company ready for the future? With KI.ready, you can unleash your full data potential and generate decisive competitive advantages. Read our flyer to find out what added value AI.ready from Quality Automation GmbH can bring you.

Create intelligent and networked production and pave your way towards Industry 4.0 and IoT.

You finally want to have order on your servers? Let’s go the way towards Industrie 4.0 together.

We develop software for web-based applications and databases – individually tailored to you!

We carry out comprehensive IT security analyses of your industrial plants and systems.