Control technology

We have unique know-how and competences with unique selling points in our main areas of expertise.

Services Automation Control technology

Services Automation Control technology

For the automation of process and production sequences, we use systems and their project planning environment according to the customer’s wishes. We are also happy to advise our customers on system selection. We realise cross-system communication for the solution of the entire automation task just as professionally as the replacement of obsolete systems, such as Siemens SIMATIC S5 by SIMATIC S7.

We have unique know-how and competences with unique selling points in our core areas. We maintain cooperations and partnerships with a selection of manufacturers, but are not limited to these. Simply contact us and we will find the right solution for your control technology needs.

Thanks to our large team of control experts, we can also offer a broad portfolio in automation technology. One of our main fields of activity is the modernisation of existing production systems. In doing so, we bring your system up to the state of the art and save you the high costs of a new acquisition.

Depending on the plant and production process, a recipe management system is indispensable. Quality Automation GmbH has already implemented recipe management systems in a wide range of industries and on various types of plant. Here, we basically orientate ourselves to the needs of our customers and, in regular exchange with the customer, develop a user interface that takes into account all the wishes and functionalities that are necessary for optimum operation.

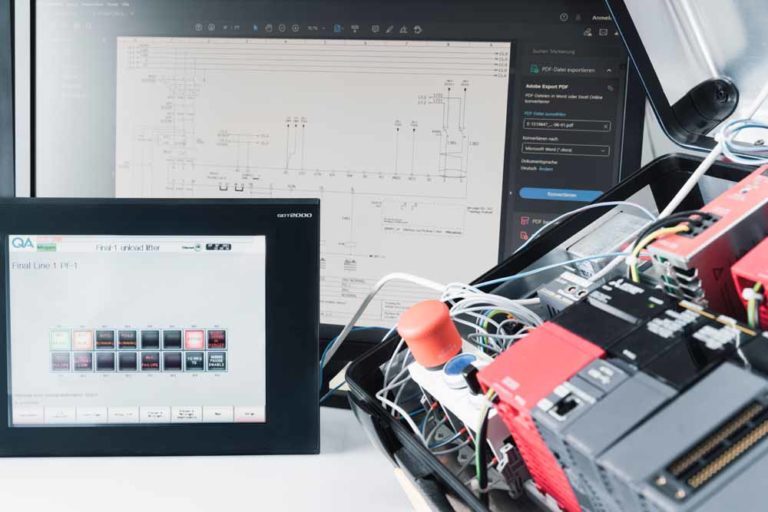

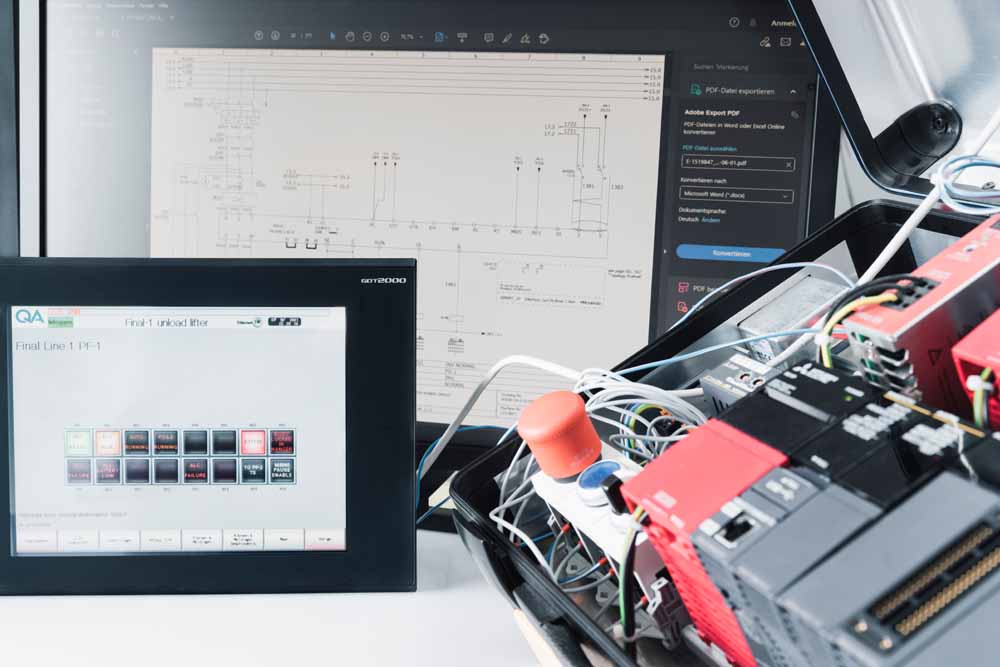

According to our own high standards, we develop new HMI user interfaces or expand existing systems. We develop operating concepts with user management, operating modes, recipe management, protocols and alarm handling.

For this purpose, we use either the industrial-grade HMI panels or the Siemens SIMATIC WinCC control system (SCADA). This stand-alone, PC-based process visualisation system is used to monitor and control processes in automation technology. WinCC runs under Windows and contains the complete SCADA functionality of a process control level. Single-user or complex multi-user systems and cross-site functions can be implemented with redundant servers and web clients. Process data can be stored in an integrated Microsoft SQL database and visualised in process images, in the form of tables or trend displays. WinCC offers a wide range of visualisation options for the HMI interfaces with standardised or self-defined image modules. Alarm messages can be displayed on the screen via the WinCC AlarmControl tool or, exported to files, printed out as a report.

We have unique know-how and competences with unique selling points in our main areas of expertise.

We are a licensed Certified Excellence Solution Partner of Bosch Rexroth and a certified Siemens Solution Partner.

From detailed planning and implementation to accompanying training – trust our experts in the field of robotics!