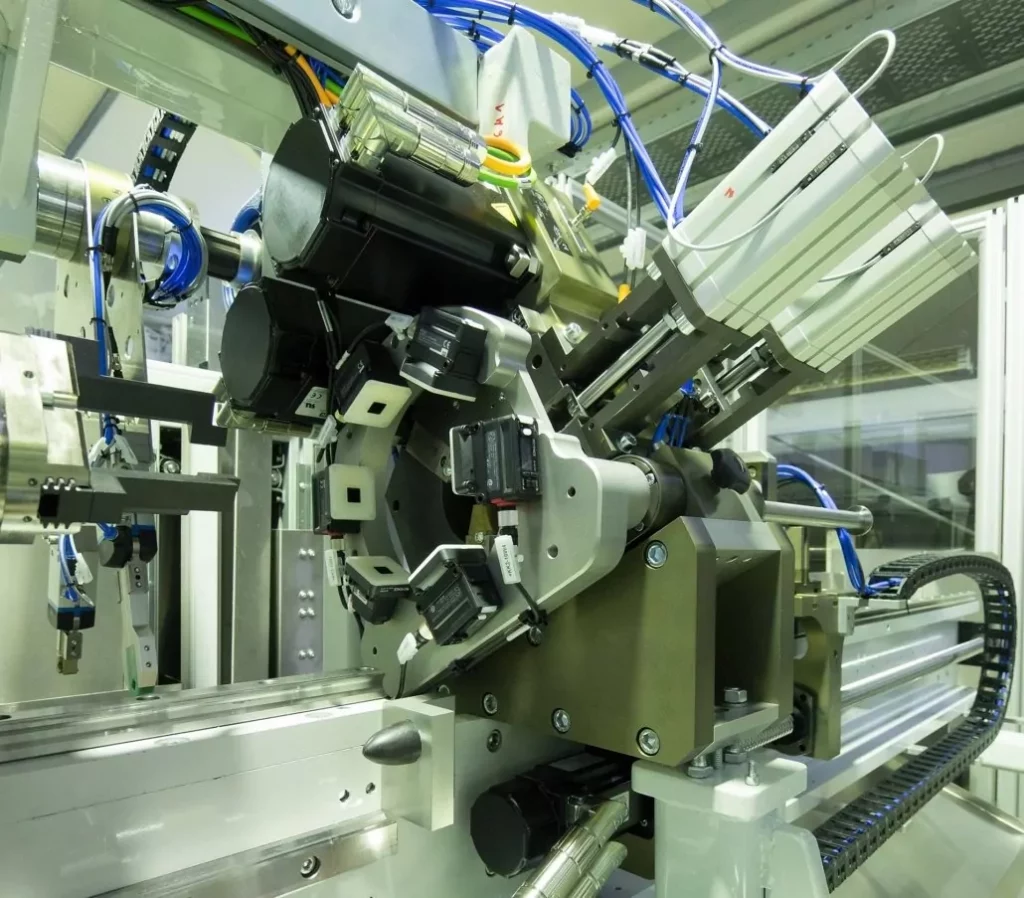

The heart of the system is the separating head of the FZH GmbH with optical recognition of the separating mark as well as the knives driven by Kollmorgen’s AKM servo motors.

Task

The task of Quality-Automation GmbH in this project was the complete automation of a pipe cutting system. An innovative system in which our customer successfully relied on the compact drive technology of Kollmorgen Europe GmbH. Electrical design, CE documentation, control cabinet construction, software development and commissioning of the system was realized by QA. As a Kollmorgen system partner, we were able to solve this task together with its sophisticated motion control application in a high-quality and timely manner.

Function of the system

The system consists of a drum magazine for buffering the blank tubes, which is loaded by the operator from the outside without contact. A handling system consisting of several servomotor-driven swivel and linear axes transports the tubes individually into the centerpiece of the system, the separating head with optical sensor technology to detect the separating mark. During linear transport into the cutting head, a laser mark is optically recognized on the tube, at which the tube is severed with high precision. The motion control application in the cutting head was realized with the high-performance AKD PDMM programmable servo amplifier. Another servomotor handling system ensures that the end products are transported away in transport crates. In doing so, a database-supported traceability of the end products was realized.

A strong partner

Quality Automation GmbH has been an official Kollmorgen system partner since 2017. From conception to detailed design, commissioning and optimization of your drive solutions, QA and Kollmorgen are at your service at the highest level. Here we also offer you customized Kollmorgen Automation Suite (KAS) training courses.

See here a video of the plant:

Mit dem Laden des Videos akzeptieren Sie die Datenschutzerklärung von YouTube.

Mehr erfahren